Wedge Wire Screen

HOME / SCREEN MESH MATERIALS / Wedge Wire Screen

Wedge Wire Screen – High-Performance Industrial Filtration & Separation Solutions

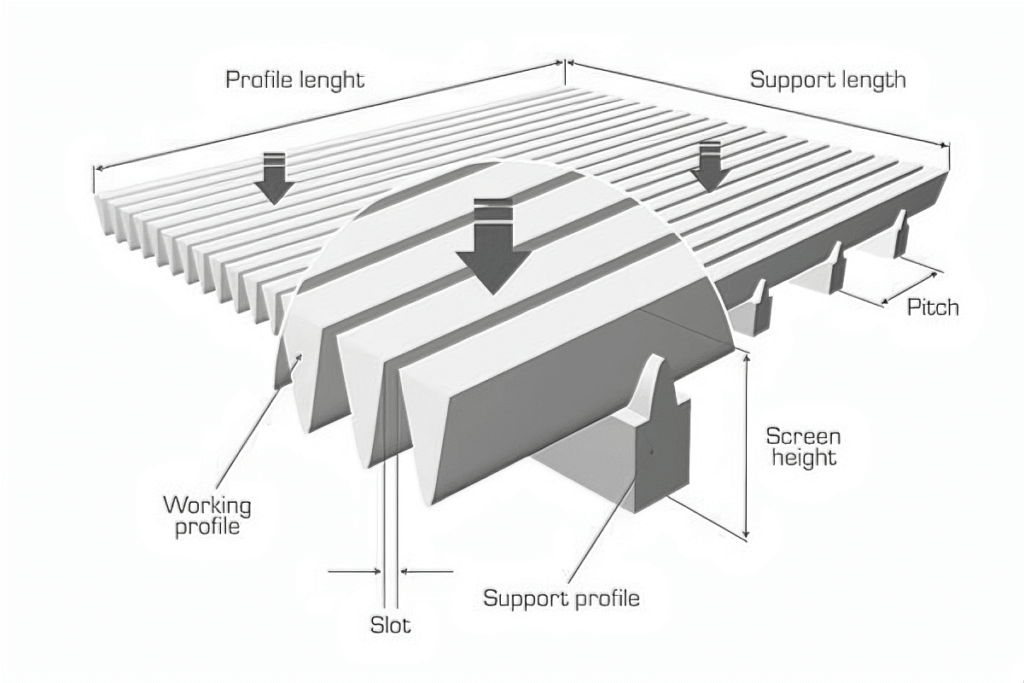

Wedge Wire Screens are advanced industrial filtration components engineered for precision solid-liquid separation across a vast range of industries. Characterized by their unique construction, these screens consist of profiled wires—typically featuring a trapezoidal or V-shaped cross-section—arranged in parallel arrays and securely welded onto robust support rods. This architecture creates a series of uniform, continuous slots, which are the critical functional element for separation. Unlike woven mesh or perforated plates, the slot width remains exceptionally consistent across the entire screen surface, enabling highly accurate particle retention and classification.

The versatility of wedge wire screens is remarkable, serving critical functions from coarse dewatering in mining and aggregate processing to ultra-fine filtration in the chemical and pharmaceutical sectors. Wedge wire constructions are available as panels, cylinders, drums, nozzles, false bottoms, and custom formed parts for filtration, dewatering, sizing and architectural uses.

Working Principle of Wedge Wire Screen

- Slot filtration: Particles larger than the slot opening are retained on the surface while liquid and smaller solids pass through the continuous V-shaped slot. The slot geometry provides one or two contact points with retained solids which helps prevent blinding and makes backwashing more effective.

- Flow & structural behavior: Because support rods carry most mechanical loads, the profile wires can be spaced to maximize open area (and therefore flow) without sacrificing rigidity. For rotating/drum or cylindrical assemblies, the wedge-wire form maintains precise slot aperture under load and rotation.

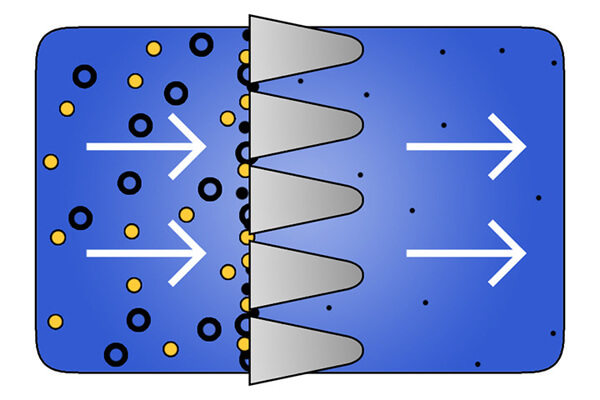

Wedge Wire Screen Filtering Process

During filtration, solid particles accumulate on the smooth, continuous surface of the wedge wire screen. This deposited layer, often referred to as the “filter cake,” functions as an additional filtration medium, capturing even finer particles. Any smaller particles that pass through the screen do not become trapped within the V-shaped, outward-widening slots, ensuring consistent flow and preventing clogging.

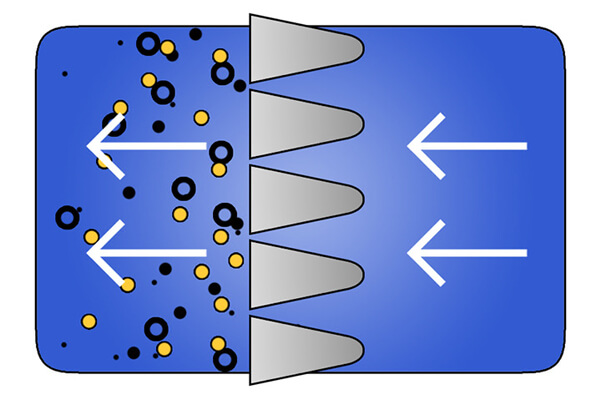

Wedge Wire Screen Backwashing Process

When the flow is reversed, the accumulated filter cake and entrapped debris are effectively lifted and flushed away from the screen surface. This backwashing action restores the screen’s open area and maintains optimal filtration performance with minimal maintenance.

Manufacturing Technologies of Wedge Wire Screen

The production of high-quality wedge wire screens demands precision engineering and controlled processes to ensure slot accuracy, structural integrity, and durability.

Material Selection

The most common material is stainless steel (grades 304 and 316), prized for its corrosion resistance and strength. Screens are also fabricated from other alloys like Hastelloy for extreme chemical environments, carbon steel for abrasive but non-corrosive duties, and plastics like PVC for specific architectural or corrosive applications.

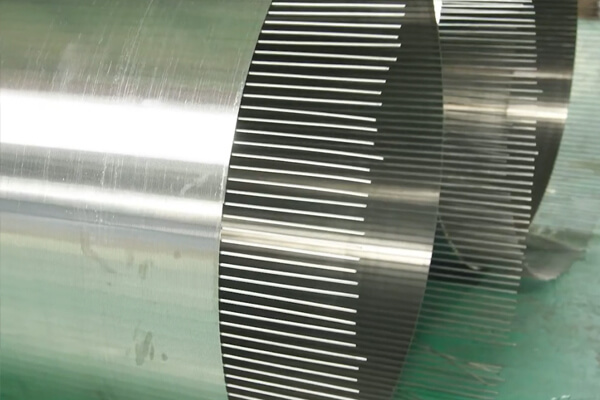

Core Welding Techniques

The primary manufacturing method involves automated resistance welding. Pre-formed profile wires are aligned parallel to each other and welded at precise contact points onto perpendicular support rods. This process is highly controlled to prevent distortion of the wires and to guarantee that the slot dimensions remain consistent within tight tolerances across the entire screen panel.

Fabrication

After welding, flat panels can be formed into cylinders, cones, or other shapes using specialized rolling and bending equipment. Cylindrical screens can also be constructed via a spiral welding technique, where a single profile wire is wound around a array of longitudinal rods.

Precision and Quality Assurance

Achieving ultra-fine slot accuracy requires a synergy of advanced technologies. This includes the development of high-precision, irregularly-shaped wires, automated welding machines with minimal thermal distortion, and sophisticated measurement systems.

Advantages of Wedge Wire Screen

Wedge wire screens offer a compelling set of benefits that make them superior to alternative filtration media like woven wire cloth or perforated plates in many applications.

- Superior Strength & Durability: The welded construction creates a rigid, monolithic structure with a high strength-to-weight ratio. It can withstand significant mechanical loads, vibration, abrasion, and high differential pressures without deformation. This results in a longer service life and reduced maintenance costs.

- Precise & Consistent Filtration: The slots are uniform and non-deforming. Unlike woven mesh where apertures can be distorted under load or during cleaning, wedge wire slots maintain their exact dimensions, ensuring reliable and predictable particle size separation throughout the screen’s life.

- High Open Area & Efficiency: The design inherently provides a large percentage of open screening area relative to the screen’s footprint. This allows for greater flow rates, reduces head loss, and improves overall separation efficiency. For example, a screen with a 1.0 mm aperture can achieve an open area exceeding 30%.

- Anti-Blinding & Self-Cleaning: The V-shaped, smooth-sided slots prevent particles from sticking. During operation or backwashing, solids are easily released, minimizing downtime for cleaning. This is a significant advantage over woven screens, which are prone to blinding.

- Design Flexibility & Customization: Screens can be engineered to exact specifications for slot size (from 20µm to 10mm+), shape (flat, cylindrical, conical), size, and material to fit virtually any application or vessel. Special profiles and coatings (like hydrophilic paint) can be applied to tackle specific process challenges.

- Cost-Effective Operation: While the initial investment may be higher than some alternatives, the long service life, minimal maintenance, and consistent performance lead to a lower total cost of ownership. Their reusability and recyclability (especially stainless steel versions) also contribute to environmental and economic sustainability.

Materials of Wedge Wire Screen

Material choice is critical for corrosion resistance, wear life, and compatibility.

| Common Materials and Their Properties | |||

| Material | Typical Grades | Key Properties | Ideal Applications |

| Stainless Steel | 304, 304L, 316, 316L | Excellent corrosion resistance, good strength, hygienic. | Water/wastewater, food & beverage, general chemical. |

| Carbon Steel | 1018, 1045 | High strength, excellent abrasion resistance, low cost. | Mining, aggregate, abrasive slurries where corrosion is not primary concern. |

| Special Alloys | Hastelloy, Monel | Exceptional resistance to acids, chlorides, and extreme corrosion. | Chemical processing, pulp & paper bleaching, offshore. |

Specification of Wedge Wire Screen

- Material: stainless steel 304, 316, 316L, Hastelloy, Monel alloy, etc.

- Wedge wire shape: triangular, tapered, and prismatic

- Common specification of wedge wire: 1.00 mm × 2.00 mm

- Support profile shape: rectangular, tapered, and teardrop-shaped

- Common specifications of support profile: 2.00 mm × 3.00 mm

- Calculation method of open area: Open Area (%) =Slot size x 100/(Slot size + Wire width)

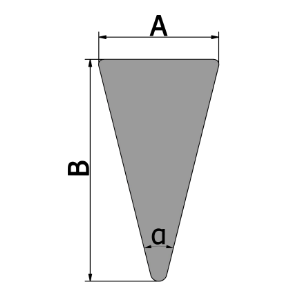

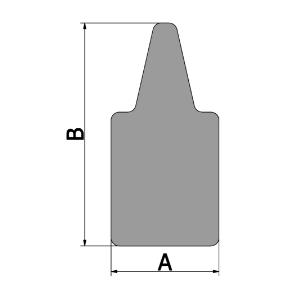

Triangular Wedge Wire Specification

| A | B | α |

| (mm) | (mm) | (°) |

| 0.5 | 1.2 | 12 |

| 0.6 | 1.2 | 22 |

| 0.75 | 1.3 | 20 |

| 1 | 2 | 20 |

| 1.5 | 2.5 | 23 |

| 1.8 | 3.7 | 23 |

| 2.2 | 4.5 | 23 |

| 2.8 | 5 | 23 |

| 3.4 | 6.5 | 23 |

| 4 | 9 | 20 |

| 5 | 10 | 24 |

| 5 | 6 | 40 |

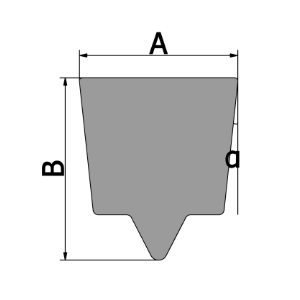

Tapered Wedge Wire Specification

| A | B | α |

| (mm) | (mm) | (°) |

| 5 | 5.5 | 6 |

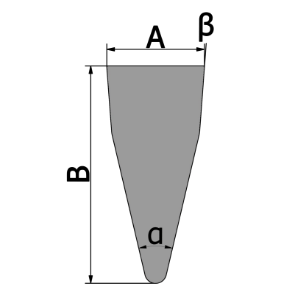

Prismatic Wedge Wire Specification

| A | B | α | β |

| (mm) | (mm) | (°) | (°) |

| 2.2 | 5 | 23 | 4 |

| 2.5 | 4 | 40 | 5 |

| 2.8 | 6.5 | 23 | 4 |

| 3.4 | 6 | 70 | 4 |

| 3.5 | 8 | 23 | 4 |

| 5 | 10 | 23 | 5 |

| 2.4 | 5 | 23 | 0 |

| 3 | 6.5 | 23 | 0 |

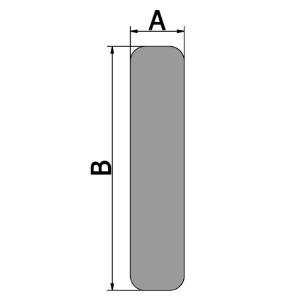

Rectangular Wedge Wire Support Profile Specification

| A | B |

| (mm) | (mm) |

| 3 | 10 |

| 2 | 10 |

| 2 | 12 |

| 2 | 15 |

| 3 | 18 |

| 3 | 20 |

| 2 | 30 |

| 3 | 38 |

Tapered Wedge Wire Support Profile Specification

| A | B |

| (mm) | (mm) |

| 2 | 3 |

| 3 | 5 |

| 4 | 8 |

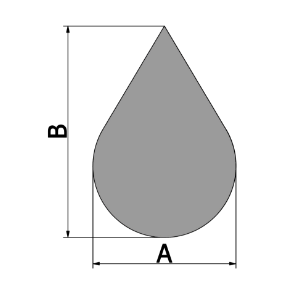

Teardrop-Shaped Wedge Wire Support Profile Specification

| A | B |

| (mm) | (mm) |

| 3.8 | 5.6 |

Wedge Wire Screen Products

Applications of Wedge Wire Screen

Wedge wire screens are ubiquitous across industry due to their robustness and adaptability. Their applications can be categorized into several key sectors.

1. Industrial and Process Separation

This is the largest application area, covering solid-liquid separation, classification, and dewatering.

- Mining & Minerals: For dewatering and sizing of coal, iron ore, sand, gravel, and aggregates on vibrating screens, sieve bends, and static filters.

- Pulp & Paper: Used as pressure screen baskets in pulp screening systems to remove contaminants and accept pulp fibers.

- Food & Beverage: For starch processing, juice extraction, brewing, and wastewater treatment, where hygiene and cleanability are paramount.

- Chemical & Pharmaceutical: As filter elements in pressure vessels, centrifuges, and fluid bed dryers for catalyst recovery, product classification, and solvent purification, utilizing fine-aperture screens.

2. Environmental and Water Management

- Water & Wastewater Treatment: As intake screens for power plants and desalination facilities, effectively reducing aquatic organism impingement/entrainment with low-velocity designs. Also used as drum screens, bar screens, and underdrain systems in sand filters for support and effluent collection.

- Sludge Dewatering: Integral part of belt filter presses, screw presses, and rotary drum thickeners to separate solids from municipal and industrial sludges.

3. Architectural and Specialized Uses

- Architectural Facades & Design: Their aesthetic appeal and functionality are leveraged for building cladding, sunscreens, balcony balustrades, and decorative interior features, offering both visual texture and ventilation.

- Oil & Gas (Downhole Screens): Specialized cylindrical screens are used in well completion for sand control, allowing hydrocarbons to flow while preventing formation sand from entering the wellbore.

4. Emerging and Niche Applications

- Biomass and Renewable Energy: For processing in biogas plants and cellulosic ethanol production.

- Electronics Industry: Ultra-fine filtration in the production of electronic materials and chemicals.

Request A Quote

* indicates required fields