Perforated Metal

HOME / SCREEN MESH MATERIALS / Perforated Metal

Perforated Metal Sheets – Durable Hole Patterns for Filtration & Architecture

Perforated metal sheet, widely known as perforated metal, is a versatile material produced by punching or stamping holes into a solid metal sheet — creating a surface that balances strength, openness and design flexibility.

Because of this unique structure, perforated metal offers excellent filtration and ventilation characteristics, while significantly reducing weight compared to a solid sheet.

Perforated metal finds use in a wide range of industrial, architectural, and decorative applications — from building facades, acoustic panels and ventilation covers, to machine guards, screening, filtration, and more.

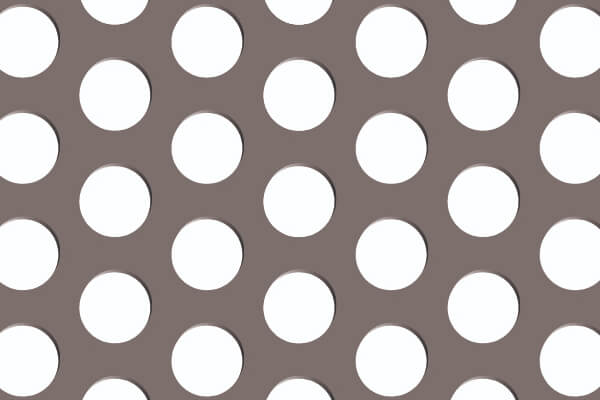

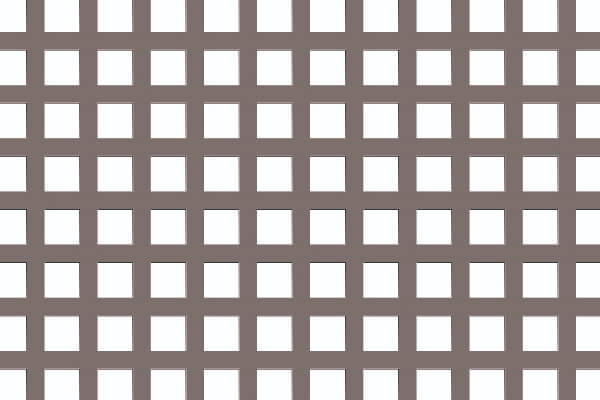

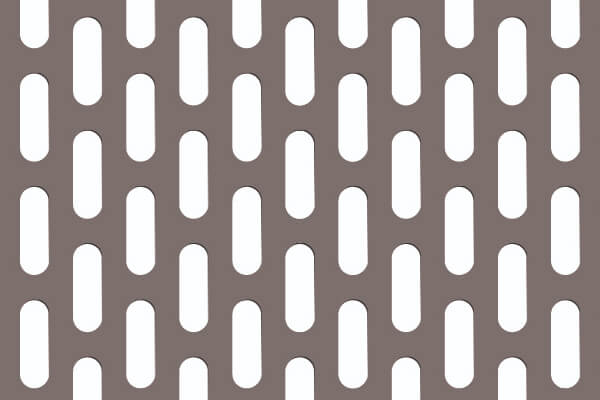

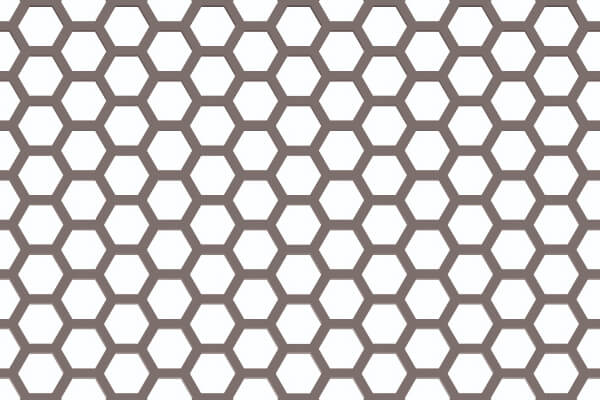

Hole Pattern of Perforated Metal Sheets

The performance and appearance of perforated metal are fundamentally determined by the hole pattern, which is specified by the shape, size, and pitch (the distance between hole centers).

| Shape | Description | Common Arrangements/Pitch | Key Applications |

| Round | The most popular and versatile hole shape. | 60° Staggered (Most common, offers great strength and varied Open Area); 45° Staggered; Straight Line (90°). | Architectural facades, filtration, speaker grilles. |

| Square | Offers a clean, linear look and a wide range of open area options. | Straight Line; Staggered. | Machine guards, display shelving, air conditioning covers. |

| Slot | Characterized by a long, narrow shape with either round or square ends. | Side Staggered; Straight Line. | Sieving, grading, and screening for liquids and solids. |

| Decorative | Includes complex shapes like Hexagonal, Triangular, Diamond, and other custom designs. | Various pitches to maximize aesthetic impact. | Ceiling panels, architectural cladding, interior design. |

Available Materials of Perforated Metal Sheets

Perforated metal can be manufactured from a wide array of metals and non-metals to suit diverse operational and environmental demands.

| Material | Key Characteristics | Typical Applications |

| Stainless Steel | Superior corrosion resistance, high strength, excellent durability. Grades 304 and 316 are standard. | Food processing, marine environments, chemical filtration, architectural outdoor use. |

| Aluminum | Lightweight, naturally resistant to rust, excellent thermal conductivity, easy to fabricate. | Ceiling panels, lightweight cladding, HVAC components, solar shading. |

| Carbon/Mild Steel | High strength, cost-effective, excellent for structural applications. | Machine guards, industrial screens, general construction. |

| Copper & Brass | Attractive appearance, anti-microbial properties, good electrical conductivity. | Decorative elements, interior design, specialized shielding. |

| Finishes & Treatments: | Anodizing, Powder Coating, Galvanizing, Polishing, and Fluorocarbon Spraying can be applied to enhance corrosion resistance and aesthetics. |

Advantages of Perforated Metal Sheets

Perforated metal offers a compelling combination of functionality, economy, and aesthetics. Key advantages include:

- Lightweight yet strong — by removing material through perforation, the sheet becomes significantly lighter than a solid metal sheet, while retaining structural strength and load-bearing capacity.

- Excellent ventilation, air flow and filtration — the open area allows air, sound, fluids, or light to pass through, making perforated metal ideal for HVAC grilles, ventilation covers, sieves, filters or outdoor shading.

- Acoustic control & sound absorption — perforated panels can help reduce noise levels or control acoustics, useful in sound-insulating enclosures, speaker grilles, or architectural acoustic cladding.

- Heat dissipation — perforated metal enables efficient heat and air exchange, which is valuable in cooling systems, enclosures for electrical equipment, or heat-sensitive installations.

- Design flexibility & aesthetic appeal — wide variety of hole patterns, shapes and materials allows creative architectural or decorative use: facades, ceilings, partitions, sunshades, interior design, custom patterns or even brand/logo cutouts.

- Cost-effectiveness and ease of fabrication — perforated metal can be produced, cut, bent, or formed with relatively low waste; standard sheet sizes and straightforward installation lower material and labor cost compared to fully custom metalwork.

- Corrosion resistance (depending on material) — when using stainless steel, aluminum, or properly coated carbon steel, perforated metal can withstand weather, moisture, and chemical exposure — yielding long service life with minimal maintenance.

Specification of Perforated Metal Sheets

General:

- Metal material: plain steel, mild steel, carbon steel, stainless steel (302, 304, 304L, 316, 316L), aluminum, copper, brass, pre-galvanized steel, hot or cold galvanized steel, etc.

- Thickness: 0.2 – 5.0 mm.

- Width by length: 1000 × 2000 mm to 2000 × 6000 mm or according to customer’s requirements.

- Standard sizes (mm): 1000 × 2000, 1000 × 2400, 1200 × 2400.

- Popular hole patterns: round hole, square hole, slotted hole, hexagonal hole, decorative hole, or customized.

- Hole diameter: 0.2 – 100 mm.

- Margin types: safe margins or no-margins.

Round hole:

- Hole size: 0.027″ – 1.0″.

- Hole centres: 0.05″ – 1.25″.

- Hole pattern: staggered and straight row.

- Sheet width: 24″ – 60″.

- Sheet length: 24″ – 144″.

- Open area: 5% – 63%.

Square hole:

- Thickness: 11–22 gauge.

- Hole size: 0.2″ – 0.75″.

- Hole centres: 0.5″ – 1″.

- Hole pattern: staggered or straight row.

- Open area: 11% – 56%.

- Width: 36″ – 48″.

- Length: 24″ – 120″.

Slotted hole:

- Thickness: 14–22 gauge.

- Hole pattern: side staggered and straight row.

- Slot width: 0.125″ – 0.2″.

- Slot length: 0.1″ – 0.75″.

- Slot shape: round end and square end.

- Slot side bar: 0.125″ – 0.25″.

- Slot end bar: 0.125″ – 0.25″.

- Open area: 41% – 74%.

- Panel width: 36″.

- Panel length: 24″ – 120″.

Hexagonal hole:

- Thickness: 14–22 gauge.

- Hole size: 0.25″ – 0.5″.

- Hole centres: 0.2813″ – 0.5625″.

- Hole pattern: staggered row.

- Open area: 35% – 80%.

- Width: 25″ – 48″.

- Length: 24″ – 120″

Decorative hole:

- Open area: 35% – 68%.

- Thickness: 11 – 24 gauge.

- Width: 36″ – 48″.

- Length (span for grating): 24″ – 120″.

We offer a range of standard industrial perforated metal models, and we can also customize products based on your design concepts to meet your specific application requirements.

Applications of Perforated Metal

Perforated metal sheets are used across many sectors — here are some of the common and versatile applications:

- Architectural and building facades, sunshades, exterior cladding and decorative panels — using perforated metal for modern, industrial-style aesthetics, while controlling sunlight, airflow, and energy efficiency.

- Ventilation, HVAC systems, air-condition guards, and airflow grilles — to provide ventilation while ensuring structural integrity and protection.

- Acoustic panels, speaker grilles, sound-absorbing enclosures — using perforation and open-area to improve acoustic performance, reduce noise or manage sound in indoor spaces.

- Industrial filtration, screening, sieving, and grading — in agriculture (grain dryers, seed sieves), food & beverage (filters, presses), fish farming, ore screening, dust filtration, etc.

- Machine guards, protective screens, safety guards, balcony railings, guardrails — offering protection while maintaining visibility and airflow.

- Non-slip surfaces, anti-skid steps, stairs, industrial floors, transport platforms — especially when combined with embossed or textured perforated sheets for safety and durability.

- Decorative & design-driven uses — interior partitions, ceilings, furniture facades, retail and hospitality décor, architectural art and branding installations with custom perforation patterns.

Additionally, because perforated metal is often recyclable and lighter than solid metal sheets, it supports greener building practices and can contribute to sustainability goals in architecture and engineering projects.

Request A Quote

* indicates required fields