Wedge Wire Sieve Bend Screen

HOME / MESH FILTER ELEMENTS / Wedge Wire Screen Filters and Components / Wedge Wire Sieve Bend Screen

Wedge Wire Sieve Bend Screen | DSM Screen | Curved Wedge Wire Screen for Water Treatment

Wedge Wire Sieve Bend Screen, also known as DSM screen or curved wedge wire screen, is a high-efficiency static screening device widely used for solid-liquid separation, dewatering, classification, and scalping processes. It is manufactured from precision wedge wire profiles resistance-welded to support rods, forming a self-supporting curved screen surface with accurately controlled slot openings.

Compared with conventional perforated plates or woven wire screens, wedge wire sieve bend screens offer superior flow capacity, excellent anti-clogging performance, and extended service life. Their robust structure and precise slot control also make them suitable for demanding applications in water treatment systems, including raw water intake pre-filtration, water well screening pretreatment, and groundwater protection processes, where reliable separation and long-term stability are critical.

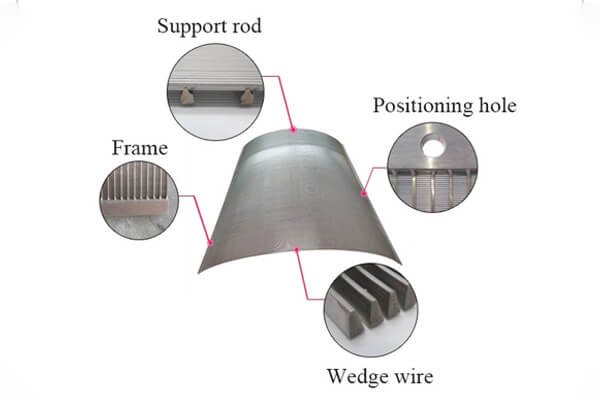

Structures of Wedge Wire Sieve Bend Screen

Structures of Wedge Wire Sieve Bend Screen

A typical Wedge Wire Sieve Bend Screen consists of the following components:

- Wedge Wire Screen Surface

Manufactured from V-shaped or trapezoidal wire profiles. The narrow slot opening faces the feed side, while the wider opening faces the discharge side, preventing particle wedging. - Support Rods

Round, flat, or wedge-shaped support rods are welded perpendicular to the screen surface to ensure structural rigidity and dimensional stability. - Curved Profile (Sieve Bend Geometry)

The screen panel is formed into a precise arc (commonly 45°, 60°, or 90°), optimizing gravity-driven separation efficiency. - Frame (Optional)

Carbon steel or stainless steel frames can be supplied for easy installation and integration into existing process equipment.

This rigid welded construction ensures uniform slot openings and high resistance to deformation under continuous flow and abrasive conditions.

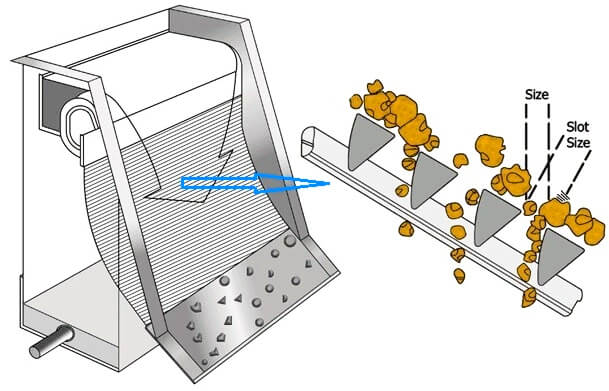

Working Principle of Wedge Wire Sieve Bend Screen

The working principle of a wedge wire sieve bend screen is based on gravity flow and centrifugal acceleration:

- Slurry or liquid-solid mixture is evenly distributed onto the upper edge of the curved screen surface.

- As the material flows downward along the curved profile, centrifugal force and gravity drive liquid and fine particles through the wedge wire slots.

- Oversized solids are retained on the screen surface and discharged at the lower end.

- The V-shaped wire profile creates a self-cleaning effect, minimizing blinding and clogging.

This non-powered, static operation makes sieve bend screens highly energy-efficient and ideal for continuous operation in water treatment, mineral processing, and industrial filtration systems.

Structures of Wedge Wire Sieve Bend Screen

Advantages of Wedge Wire Sieve Bend Screen

- High Screening Efficiency

Curved geometry significantly increases effective screening area compared with flat panels. - Excellent Anti-Clogging Performance

V-shaped wedge wire slots prevent particle lodging and reduce maintenance frequency. - Precise Slot Control

Slot openings can be manufactured with high accuracy, ensuring consistent separation performance. - Robust and Long Service Life

All-welded construction provides excellent resistance to abrasion, corrosion, and mechanical stress. - Low Operating Cost

No moving parts, no power consumption, and minimal maintenance requirements. - Versatile Integration

Can be used as a standalone unit or as a pre-screen before water well screens, intake screens, or filtration systems.

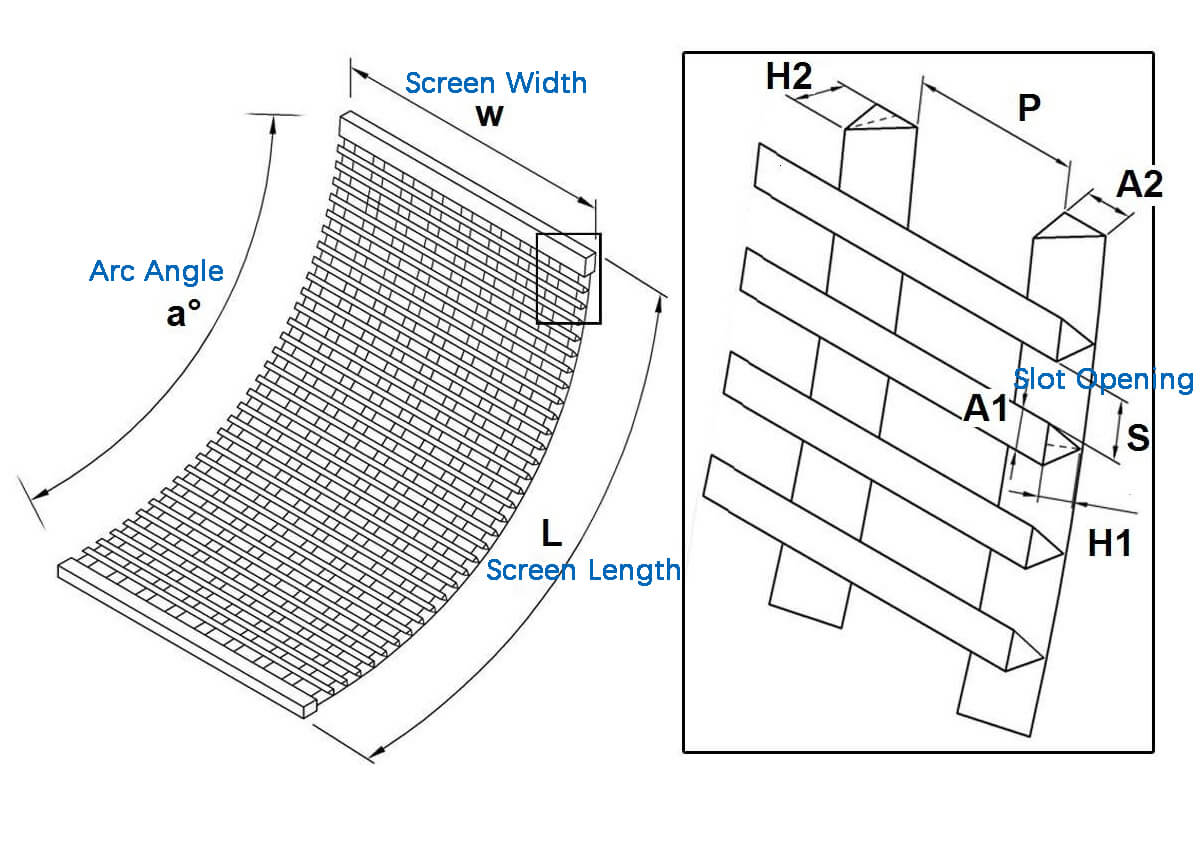

Specification of Wedge Wire Sieve Bend Screen

Drawing of Wedge Wire Sieve Bend Screen

Wedge Wire Sieve Bend Screens can be custom-manufactured according to process requirements. Typical technical parameters are shown below:

| Parameter | Standard Range |

| Screen Type | Curved (Sieve Bend / DSM Screen) |

| Arc Angle | 45°, 60°, 90° (custom angles available) |

| Slot Opening | 0.1 mm – 3.0 mm (customizable) |

| Supporting Profile Size | 2x3mm (Trapezoid), 3x5mm, 3x6mm, 5x8mm, 5x6mm (Trapezoid), 4x7mm (Trapezoid) |

| Surface Profile Size | 0.75×1.35mm, 0.76×1.5mm, 1x2mm, 1.2×2.3mm, 1.5×2.5mm, 2x3mm, 2x4mm, 2.5x4mm, 2x5mm, 3x5mm, 3x6mm |

| Screen Width | Up to 2000 mm |

| Screen Length | Up to 3000 mm |

| Available Materials | Stainless Steel 304, 316L, 2205 Duplex, 2507 Super Duplex, Carbon Steel |

| Surface Finish | Pickled, polished |

| Installation Type | Frame-mounted or direct installation |

Applications of Wedge Wire Sieve Bend Screen

Wedge Wire Sieve Bend Screens are widely used across multiple industries, including:

- Water Treatment & Water Intake Systems

- Raw water pre-screening

- Protection of pumps and downstream water well screens

- Groundwater and surface water filtration pretreatment

- Mining & Mineral Processing

- Coal washing

- Ore classification

- Dewatering and desliming

- Industrial Wastewater Treatment

- Primary solid-liquid separation

- Sludge thickening and recovery

- Food & Beverage Processing

- Starch separation

- Sugar and grain processing

- Pulp and fiber recovery

- Pulp & Paper Industry

- Fiber recovery

- White water screening

Its reliability and efficiency make it an ideal upstream screening component for systems incorporating wedge wire water well screens and intake filtration assemblies.

Request A Quote

* indicates required fields