Wedge Wire Screen Cylinders

HOME / MESH FILTER ELEMENTS / Wedge Wire Screen Filters and Components / Wedge Wire Screen Cylinders

Wedge Wire Screen Cylinders | Stainless Steel Wedge Wire Filter Cylinders

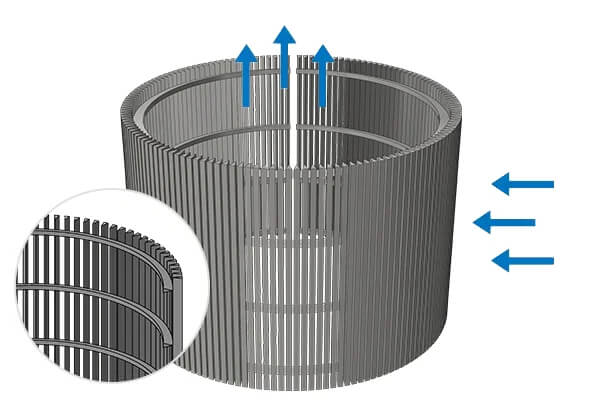

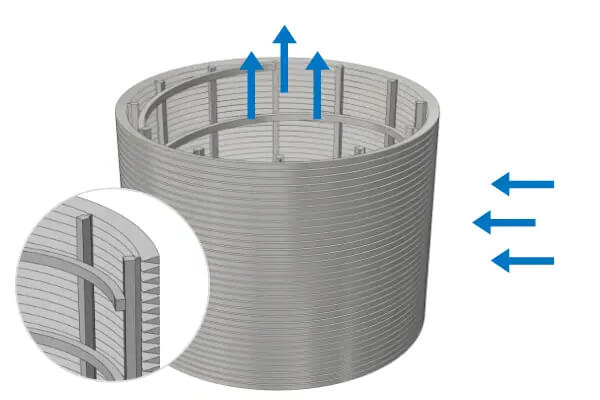

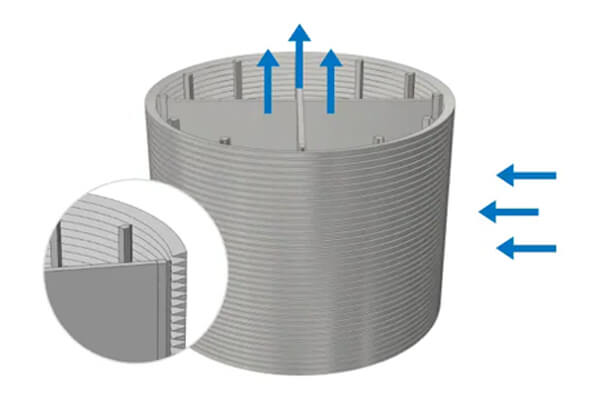

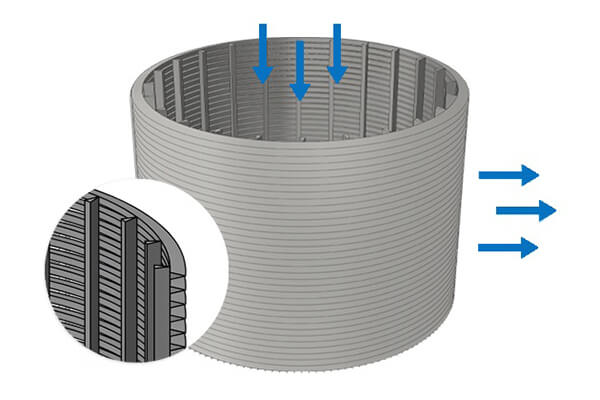

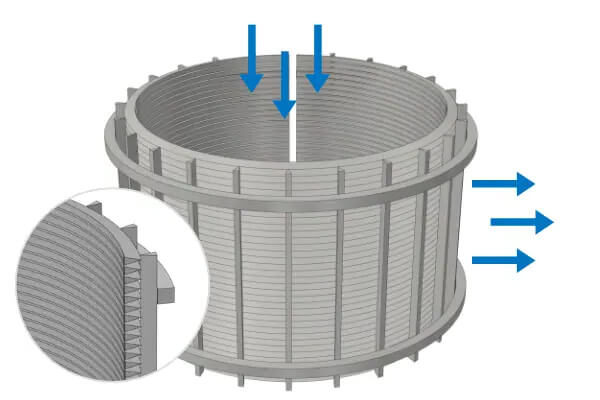

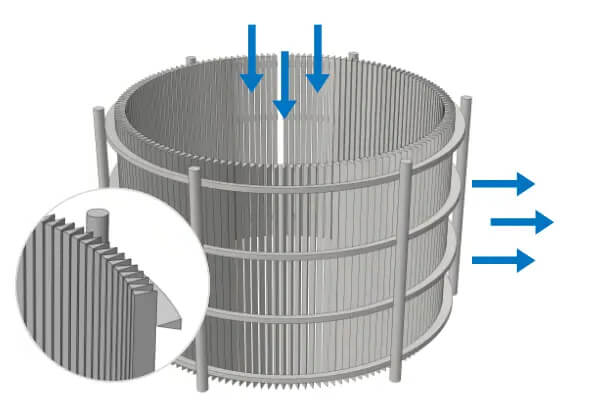

Wedge Wire Screen Cylinders are high-performance filtration and separation components engineered for durability and efficiency. They are constructed by helically or axially welding precisely profiled wedge wire onto robust longitudinal support rods. The defining feature is the wedge-shaped wire profile, which creates continuous, uniform slots that are wider on the inside and taper to a narrow opening on the outside. This innovative design minimizes particle blinding, ensures consistent performance, and provides a high open area coupled with exceptional structural integrity.

These cylinders are essential across industries for liquid-solid separation, screening, and distribution. They are widely utilized in water treatment, mineral processing, food & beverage production, chemical processing, and pulp & paper manufacturing. Compared to traditional solutions like perforated plates or woven wire mesh, wedge wire cylinders offer superior flow rates, longer service life, reliable slot accuracy, and robust performance in demanding operating environments.

Types & Configurations of Wedge Wire Screen Cylinders

Wedge wire screen cylinders can be engineered in various configurations to meet specific hydraulic, pressure, and installation requirements.

By Flow Direction

Outside-to-Inside (O/I) Flow: The standard configuration for most pressure vessel filters. Fluid enters from the outer surface and is collected inside, retaining contaminants on the external surface for easy removal via backwashing.

Inside-to-Outside (I/O) Flow: Designed for internal feed distribution, commonly used in underdrain systems, resin traps, distributor pipes, and specific process filters where flow originates from within the cylinder.

By Structural Design

Standard Cylindrical Screen: Straight-walled cylinders with uniform slot openings, suitable for a broad range of standard filtration duties.

Flanged Cylinders: Integrated with welded flanges (e.g., ANSI, DIN) for secure, leak-proof installation into pressure vessels, tanks, or pipeline systems.

Reinforced Cylinders: Built with additional external support rings, heavier-gauge support rods, or specialized end connections to withstand high differential pressure, large diameters, or significant mechanical loads.

Advantages of Wedge Wire Screen Cylinders

- Non-Blinding Slot Design: The tapered V-shaped slot allows particles smaller than the slot to pass through freely, while larger particles are retained without becoming lodged, significantly reducing clogging.

- High Open Area & Low Pressure Drop: The efficient design provides a greater percentage of open area than perforated screens or mesh, enabling higher flow rates with minimal energy loss.

- Exceptional Strength & Durability: The all-welded construction ensures outstanding resistance to mechanical deformation, vibration, shock loads, and thermal cycling.

- Precision Filtration: Slot openings can be manufactured consistently within tight tolerances, from 0.05 mm (50 microns) upwards, ensuring accurate and repeatable separation.

- Corrosion & Abrasion Resistance: Available in a comprehensive range of materials, including various stainless steels and specialty alloys, to handle corrosive, abrasive, and high-temperature processes.

- Long Service Life & Easy Maintenance: The smooth, hard surface facilitates effective cleaning via backwashing, CIP (Clean-in-Place), or mechanical methods, ensuring extended operational cycles and reduced downtime.

Specification of Wedge Wire Screen Cylinders

Wedge wire screen cylinders can be custom-manufactured according to project drawings or application parameters.

| Standard Technical Parameters | |

Parameter | Range / Options |

| Slot Opening | 0.05 mm – 5.0 mm |

| Cylinder Diameter | 25 mm – 2000 mm |

| Length | Up to 6000 mm (longer on request) |

| Wire Profile | V-shaped (wedge wire) |

| Support Rod Type | Round, triangular, or wedge |

| Flow Direction | Out-to-In / In-to-Out |

| End Connections | Plain, Flanged, Threaded, Weld Ring |

| Surface Finish | Pickled, Polished, Electro-polished |

| Manufacturing Tolerance | ±0.02 mm (slot opening) |

Available Materials:

- Stainless Steel: SS304, SS316, SS316L, SS321, SS904L

- Duplex & Super Duplex Stainless Steel

- Nickel Alloys: Inconel, Monel, Hastelloy

- Carbon Steel (coated or treated)

- Other alloys available upon request

Applications of Wedge Wire Screen Cylinders

Wedge wire screen cylinders are used across a wide range of industrial sectors:

- Water & Wastewater Treatment

Intake filtration, tertiary filtration, sludge dewatering, backwash filters - Oil & Gas / Petrochemical

Process filtration, catalyst retention, sand control, cooling water filtration - Mining & Mineral Processing

Dewatering screens, classification, tailings treatment - Food & Beverage Industry

Sugar filtration, starch processing, beverage clarification, grain separation - Pulp & Paper Industry

Stock preparation, fiber recovery, white water filtration - Chemical & Pharmaceutical Processing

Solid-liquid separation, reactor filtration, resin retention

Request A Quote

* indicates required fields