Single Layer Sintered Mesh

HOME / MESH FILTER ELEMENTS / Wedge Wire Screen Filters and Components / Wedge Wire Filter Nozzles

Wedge Wire Filter Nozzles | Stainless Steel Underdrain Filter Nozzles

Wedge Wire Filter Nozzles, also known as wedge wire underdrain nozzles or stainless steel filter nozzles, are precision-engineered filtration components widely used in water treatment, filtration systems, and process industries. Manufactured from V-shaped (wedge-shaped) wire welded onto robust support rods, these nozzles provide a continuous slot structure that ensures accurate filtration, high mechanical strength, and excellent resistance to clogging.

Compared with conventional perforated or mesh-type filter nozzles, wedge wire filter nozzles offer superior hydraulic performance, longer service life, and stable filtration efficiency. They are typically installed in gravity filters, pressure filters, ion exchange columns, media retention systems, and underdrain systems for potable water, wastewater, and industrial process fluids.

Advantages of Wedge Wire Filter Nozzles

- Continuous Slot Design

Ensures precise filtration and excellent media retention while minimizing pressure drop. - Superior Anti-Clogging Performance

The V-shaped wire profile widens outward, preventing particle wedging and facilitating self-cleaning during backwashing. - High Mechanical Strength

Fully welded construction provides outstanding load-bearing capacity and resistance to deformation. - Uniform Flow Distribution

Optimized slot arrangement ensures even water collection and backwash distribution across the filter bed. - Excellent Corrosion and Temperature Resistance

Manufactured from stainless steel and high-alloy materials, suitable for aggressive chemical and high-temperature environments. - Long Service Life & Low Maintenance

Durable structure reduces replacement frequency and operating costs over the system’s lifecycle.

Specification of Wedge Wire Filter Nozzles

Types of Wedge Wire Filter Nozzles

Wedge wire filter nozzles are available in multiple structural configurations to meet different installation and process requirements:

- Threaded Type Filter Nozzles

Designed with male or female threads (NPT, BSP, or custom standards), these nozzles allow quick and secure installation onto filter laterals or headers. They are the most commonly used type in water treatment and media filters. - Long Handle / Stem Type Filter Nozzles

Featuring an extended stem, this type is suitable for deep filter floors or thick concrete underdrain systems, ensuring reliable anchoring and uniform water distribution. - Flat Bottom / Plate Mounted Filter Nozzles

Used where welding or bolting onto a plate or header is required. These nozzles are often applied in custom-engineered filtration vessels. - Single Head & Double Head Filter Nozzles

Single-head nozzles are standard for most filtration systems, while double-head designs provide higher flow capacity and enhanced backwash performance. - Custom Engineered Wedge Wire Nozzles

Slot size, nozzle diameter, length, flow rate, connection type, and material can be fully customized to match specific process conditions and system designs.

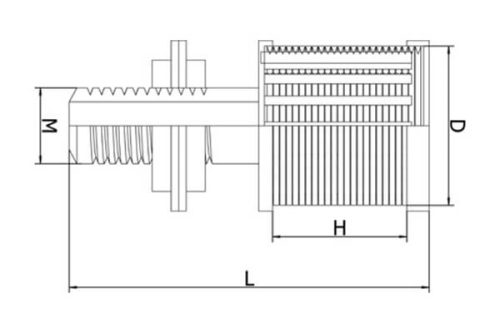

Single Head Wedge Wire Nozzle

| Specification of Single Head Wedge Wire Nozzle | ||||||||

| Model | Slot (mm) | Outline Dimension (mm) | Filtration Capacity | Material Grade | ||||

| D | H | L | M (thread nipples) | Area (mm2) | Tons per hour | |||

| PFM-SN-45-40 | 0.2–0.5 | 45 | 40 | 75 | M20, M24, 3/4″ NPT, 1″ NPT, 3/4″ BSPT, 1″ BSPT | 280 | 0.5 T/H | 304, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2 |

| PFM-SN-53-45 | 0.2–0.5 | 53 | 45 | 95 | 450 | 1.0 T/H | ||

| PFM-SN-57-50 | 0.2–0.5 | 57 | 50 | 95 | M24, M32, 1″ NPT, 1-1/2″ NPT, 1″ BSPT, 1-1/2″ BSPT | 660 | 1.5 T/H | |

| PFM-SN-57-60 | 0.2–0.5 | 57 | 60 | 110 | 800 | 2.0 T/H | ||

| PFM-SN-70-70 | 0.2–0.5 | 70 | 70 | 120 | 1200 | 3.0 T/H | ||

| PFM-SN-82-50 | 0.2–0.5 | 82 | 60 | 150 | M42, 1″ NPT, 2″ NPT, 2″ BSPT | 1200 | 3.0 T/H | |

Notes:

| ||||||||

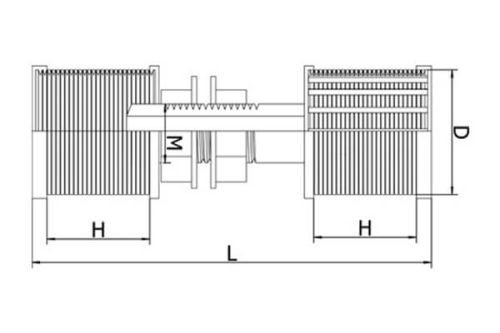

Double Head Wedge Wire Nozzle

| Specification of Double Head Wedge Wire Nozzle | ||||||||

| Model | Slot (mm) | Outline Dimension (mm) | Filtration Capacity | Material Grade | ||||

| D | H | L | M | Area (mm2) | Tons per hour | |||

| PFM-DN-45-5-A | 0.2–0.5 | 45 | 35 | according to order | M24 | 660 | 1.0 T/H | 304, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2 |

| PFM-DN-45-5-B | 0.2–0.5 | 45 | 45 | M24 | 800 | 1.5 T/H | ||

| PFM-DN-53-6-A | 0.2–0.5 | 53 | 35 | M24 | 1020 | 2.0 T/H | ||

| PFM-DN-53-6-B | 0.2–0.5 | 53 | 45 | M32 | 1280 | 3.0 T/H | ||

| PFM-DN-57-7-A | 0.2–0.5 | 57 | 40 | M32 | 1260 | 3.0 T/H | ||

| PFM-DN-57-7-B | 0.2–0.5 | 57 | 50 | M32 | 1560 | 4.0 T/H | ||

Notes:

| ||||||||

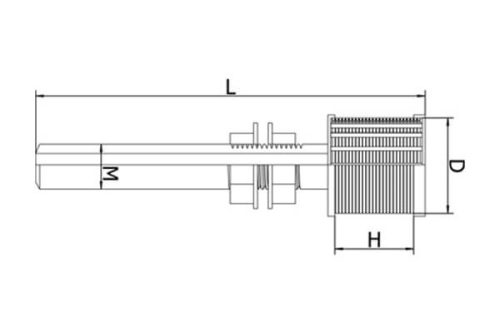

Long Hand Wedge Wire Nozzle

| Specification of Long Hand Wedge Wire Nozzle | |||||||||

| Model | Slot (mm) | Outline Dimension (mm) | Filtration Capacity | Material Grade | |||||

| D | H | L | M | L1 | Area (mm2) | Tons per hour | |||

| QSLN45-11-A | 0.2–0.5 | 45 | 35 | 150 | M20 | according to the installation holes plate | 330 | 0.5 T/H | 304, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2 |

| QSLN45-11-B | 0.2–0.5 | 45 | 45 | 160 | M24 | 400 | 0.5 T/H | ||

| QSLN53-12-A | 0.2–0.5 | 53 | 45 | 170 | M24 | 510 | 1.0 T/H | ||

| QSLN53-12-B | 0.2–0.5 | 53 | 50 | 180 | M32 | 640 | 1.5 T/H | ||

| QSLN57-13-A | 0.2–0.5 | 57 | 40 | 190 | M32 | 630 | 1.5 T/H | ||

| QSLN57-13-B | 0.2–0.5 | 57 | 50 | 200 | M32 | 780 | 2.0 T/H | ||

| Notes: L1 is determined by the thickness of the perforated plate and the lining glue provided by the user. The water wedge wire nozzle is equipped with a rubber gasket, a steel gasket and one or two stainless steel nuts of the same material. Specifications not listed in the chart, processing production according to user requirements. M, G, BSPP pipe thread are available. Filtration Capacity depends on 0.2mm screen slot for reference. To learn more accurate information, please contact our sales engineer. | |||||||||

Custom Engineered Wedge Wire Nozzles

| Slot Size | 0.05 – 1.0 mm (custom available) |

| Nozzle Diameter | 25 – 300mm (custom available) |

| Nozzle Length | 50 – 800 mm (custom available) |

| Flow Rate | Customized based on slot size & design |

| Wire Profile | V-shaped (wedge wire) |

| Support Rod Type | Round or flat support rods |

| Connection Type | Male/Female Thread, Plate Mount, Welded |

| Thread Standards | NPT, BSP, Metric, or custom |

| Available Materials | SS304, SS316L, Duplex SS, Hastelloy, Monel |

| Surface Finish | Pickled, polished, or electropolished |

| All dimensions and parameters can be customized according to filtration system design and operating conditions. | |

Applications of Wedge Wire Filter Nozzles

Wedge wire filter nozzles are widely used across municipal and industrial filtration systems, including:

- Drinking Water Treatment Plants

Rapid sand filters, gravity filters, and underdrain systems. - Wastewater Treatment & Reuse Systems

Tertiary filtration, polishing filters, and backwash systems. - Industrial Process Water Filtration

Power plants, petrochemical facilities, steel mills, and chemical processing. - Ion Exchange & Demineralization Systems

Resin retention in softeners and deionization columns. - Desalination & Seawater Pretreatment

Media filters for RO pretreatment systems. - Food & Beverage Industry

Process water filtration and clarification systems.

Request A Quote

* indicates required fields