Knitted Mesh Engine Breathers

HOME / MESH FILTER ELEMENTS / Knitted Mesh Filters and Components / Knitted Mesh Engine Breathers

Knitted Mesh Engine Breathers | Compressed Engine Breather Pads

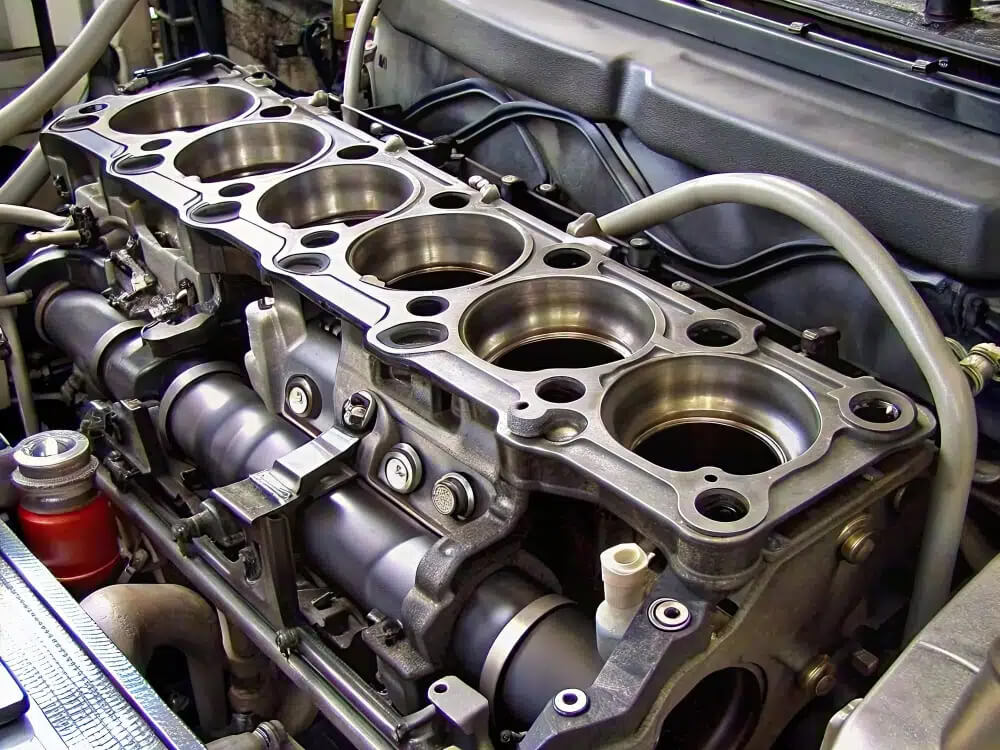

Knitted Mesh Engine Breathers are high-performance filtration components engineered to manage internal pressure and separate oil from venting air in internal combustion engine systems. They are manufactured from precision knitted wire mesh and are widely used in automotive, marine, and industrial applications where effective air/oil separation, low pressure loss, and emission control are critical.

Engine breathers play a crucial role in crankcase ventilation systems by allowing pressure equalization while capturing oil mist and preventing contaminant release to the environment, supporting engine longevity and regulatory compliance.

Advantages of Knitted Mesh Engine Breathers

- High Filtration Efficiency

Engine breathers remove up to 99% of oil droplets in the 3–10 micron size range, ensuring effective separation of oil mist from vented air and minimizing oil loss and emissions. - Minimal Pressure Drop

The knitted mesh structure creates a high free-volume ratio that allows maximum airflow with a very low pressure drop, typically less than 5 millibar, which helps maintain optimal engine breathing and performance. - Corrosion and Temperature Resistance

Standard elements are produced from high quality galvanised steel. For demanding environments, options include stainless steel and alternative alloy materials to enhance temperature tolerance and corrosion resistance. - Customisable Form Factors

Knitted mesh elements can be supplied in a variety of configurations — including die-compressed, layered, or spiral-wound formats — to match different breather housings and cavity geometries. - Ease of Installation and Maintenance

The breathable mesh is engineered for straightforward integration into existing breather housings or oil filler caps. Its simple structure facilitates replacement and reduces maintenance downtime.

Specification of Knitted Mesh Engine Breathers

| Attribute | Typical Range / Value |

| Media Type | Knitted Wire Mesh |

| Filtration Efficiency | ≥ 99% for 3–10 μm oil droplets |

| Pressure Drop | ≤ 5 mbar under normal airflow |

| Free-Volume Ratio | High porosity for efficient airflow |

| Materials | Galvanised steel (standard), Stainless steel (optional), other alloys available |

| Element Forms | Die-compressed; Layered; Spiral-wound |

Applications of Knitted Mesh Engine Breathers

- Automotive Engines: Engine crankcase ventilation breather elements for cars, trucks, and commercial vehicles.

- Marine Engines: Breathable filtration for marine power units exposed to corrosive environments.

- Industrial Power Systems: Generators and heavy machinery requiring efficient emission control and pressure equalization.

- Oil Filler Cap Breathable Filters: Integrated breather solutions for oil filler caps to prevent oil mist release and ensure clean air ingress.

Request A Quote

* indicates required fields