Knitted Mesh Filters and Components

HOME / MESH FILTER ELEMENTS / Knitted Mesh Filters and Components

Knitted Mesh Filters & Components for Filtration, Separation and Sealing | PFM SCREEN

Knitted Mesh Filters and Components are engineered functional elements manufactured by interlooping metal or polymer wires into continuous, resilient mesh structures. This unique construction enables a combination of filtration, separation, sealing, damping, and shielding functions within a single component.

Compared with woven or sintered media, knitted mesh offers superior elasticity, compressibility, and structural stability under dynamic operating conditions. These characteristics make knitted mesh components particularly suitable for applications involving vibration, pressure fluctuation, thermal cycling, or repeated mechanical loading.

PFM SCREEN designs and manufactures knitted mesh filters and components for demanding industrial environments, supplying both standard solutions and application-specific designs for automotive, process industries, energy systems, and safety-critical equipment.

Knitted Mesh Filters and Components Product Options

PFM SCREEN provides a broad range of knitted mesh filters and components, engineered to meet diverse functional and regulatory requirements.

All product types can be customized in material, wire diameter, mesh density, geometry, and dimensions to align with specific operating conditions and performance targets.

PFM SCREEN’s product range includes:

Knitted Wire Mist Eliminators

High-efficiency gas–liquid separation elements designed to remove entrained droplets from process gas streams. Widely used in chemical processing, petrochemical plants, and environmental control systems.

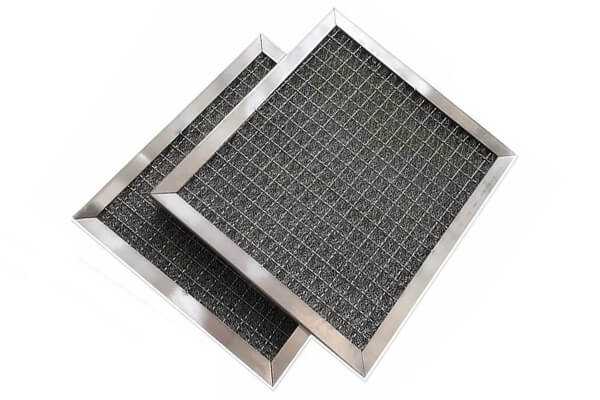

Framed Knitted Mesh Filters

Knitted mesh media integrated into rigid metal frames to ensure dimensional stability, ease of installation, and consistent filtration performance in air and liquid filtration systems.

Compressed Knitted Mesh Filters

High-density components produced by controlled compression of knitted mesh, allowing precise control of porosity, permeability, and mechanical strength.

Knitted Mesh Airbag Filters

Precision safety components used in automotive airbag inflator systems to filter particulates, regulate gas flow, and ensure reliable deployment performance.

Knitted Mesh Engine Breathers

Oil mist separation elements designed for engine crankcase ventilation systems, improving oil recovery while maintaining stable airflow.

Knitted Wire Mesh Gaskets

Resilient sealing components offering reliable compression recovery, electrical conductivity, and EMI/RFI shielding in demanding sealing applications.

Advantages of PFM SCREEN Knitted Mesh Filters and Components

- Engineering Flexibility

Knitted mesh structures can be layered, compressed, framed, or formed into complex shapes without compromising functional integrity. - Extensive Material Options

Available materials include stainless steel, copper, nickel, Monel, Inconel, titanium, carbon steel, and other high-performance alloys. - Mechanical Resilience and Durability

Excellent elasticity and recovery properties under repeated compression, vibration, and thermal cycling. - Optimized Filtration Performance

Controlled pore structure enables efficient particle capture, mist separation, and flow regulation. - Resistance to Harsh Environments

Suitable for high temperatures, corrosive media, and chemically aggressive operating conditions. - Consistent Manufacturing Quality

Strict process control ensures repeatable performance and long-term reliability.

Applications of Knitted Mesh Filters and Components

PFM SCREEN knitted mesh filters and components are widely applied across multiple industries, including:

- Automotive and transportation systems

- Chemical and petrochemical processing

- Oil, gas, and energy equipment

- Environmental protection and emission control

- Industrial air and liquid filtration

- Safety systems and precision engineering

- EMI/RFI shielding and conductive sealing

Their adaptability allows knitted mesh solutions to perform reliably in both standardized industrial systems and highly customized engineering applications.

Why Choose PFM SCREEN Knitted Mesh Filters and Components?

- Specialized Manufacturing Expertise

Deep technical experience in knitted mesh structures and functional filtration components. - Application-Driven Customization

Design support from concept and prototyping through to series production, based on drawings or performance specifications. - Stable Production and Supply Capability

Reliable manufacturing capacity supporting long-term global partnerships. - Technical Support and Engineering Communication

Clear, efficient communication with engineering and procurement teams throughout the project lifecycle. - Proven International Supply Experience

Products supplied to customers across Europe, North America, and other global markets.

PFM SCREEN delivers knitted mesh filters and components that meet international industrial standards, supporting system performance, safety, and long-term operational reliability.