Sintered Wire Mesh Filter Disc

HOME / MESH FILTER ELEMENTS / Filter Discs / Sintered Wire Mesh Filter Disc

Customizable Sintered Wire Mesh Filter Discs for Chemicals, Food & Pharma

A Sintered Wire Mesh Filter Disc is a high-performance filtration component made by layering metal wire meshes and bonding them through a sintering process. This process produces a rigid, durable, and corrosion-resistant disc capable of withstanding high temperatures, pressures, and aggressive chemical environments.

Woven Wire Mesh Filter Discs can also be cut into circular shapes or customized according to user-specific designs, providing flexibility for various equipment and filtration requirements.

Sintered discs are widely used in industries such as chemical, pharmaceutical, food and beverage, oil and gas, water treatment, and high-temperature industrial processes.

Types of Sintered Wire Mesh Filter Discs Materials

Sintered wire mesh filter discs are available in different material constructions to meet various filtration needs:

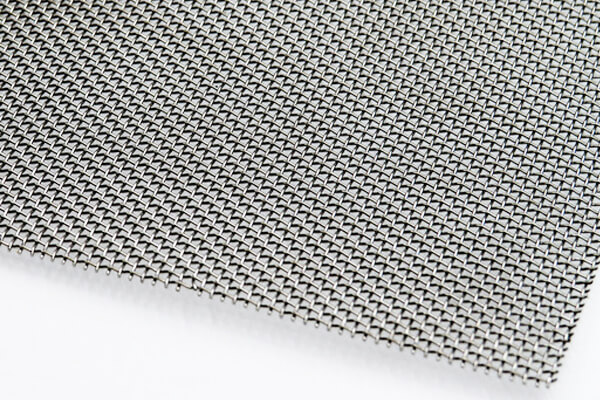

Single Layer Sintered Mesh

Made from a single layer of sintered wire mesh, this type provides basic filtration for liquids and gases. It is ideal for applications requiring moderate precision and mechanical strength.

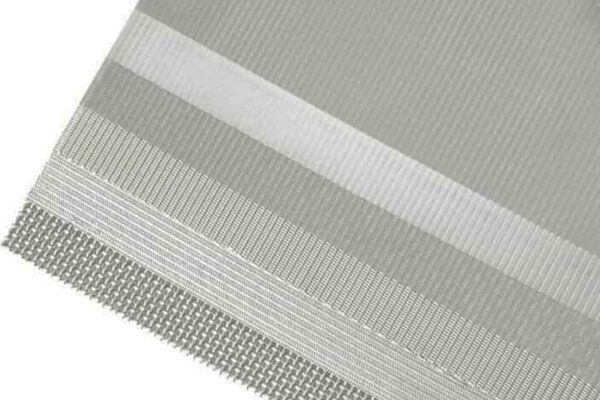

Multiple Layer Sintered Mesh

Consists of two or more sintered mesh layers bonded together, offering higher mechanical strength, uniform filtration, and improved durability. Suitable for demanding industrial applications.

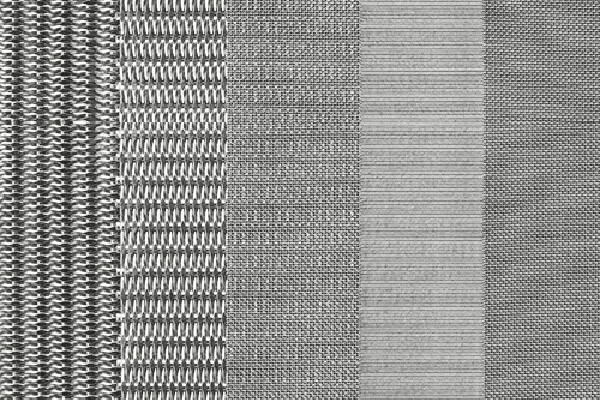

Five-Layer Sintered Mesh

Composed of five layers of sintered wire mesh, this type delivers maximum strength, finest filtration, and long service life. Often used in chemical, pharmaceutical, and high-pressure filtration systems.

Advantages of Sintered Wire Mesh Filter Disc

Sintered Wire Mesh Filter Discs offer a combination of mechanical strength, chemical resistance, and filtration precision, making them ideal for industrial applications. Key advantages include:

- High Mechanical Strength – The sintering process fuses the wire mesh layers into a solid, rigid structure, ensuring discs withstand high pressure and heavy flow conditions without deformation.

- Precise and Uniform Filtration – Multi-layer construction provides consistent pore size and even flow distribution, achieving accurate separation of particles down to micrometer levels.

- Corrosion and Chemical Resistance – Made from stainless steel, nickel, or other corrosion-resistant alloys, the discs can handle aggressive chemical fluids, acids, and alkalis.

- High Temperature Tolerance – Sintered discs maintain structural integrity under elevated temperatures, suitable for high-temperature industrial processes.

- Long Service Life and Low Maintenance – Durable design and corrosion resistance reduce the need for frequent replacement or cleaning, lowering operational costs.

- Customizable Sizes and Shapes – Discs can be produced in circular or user-defined designs to fit specific equipment, ensuring seamless integration in various filtration systems.

- Multi-Layer Options – Single, multiple, or five-layer constructions allow selection of the ideal balance between filtration precision and mechanical strength for the intended application.

Specification of Sintered Wire Mesh Filter Disc

| Parameter | Details |

| Material | Stainless Steel (304, 316, 316L), Nickel, Monel, etc. |

| Pore Size | 1 µm – 500 µm (customizable) |

| Thickness | 1 mm – 20 mm (depending on layers) |

| Diameter | 10 mm – 500 mm (customizable) |

| Shape | Round or customized according to design |

| Construction Type | Single Layer / Multiple Layer / Five-Layer |

Applications of Sintered Wire Mesh Filter Disc

Sintered Wire Mesh Filter Discs are highly versatile and used across many industries:

- Chemical Industry – Filtration of corrosive liquids, acids, solvents, and intermediates in reactors, pipelines, and vessels.

- Pharmaceuticals – Sterile filtration, separation of fine powders, and purification of liquids during drug production.

- Food and Beverage Processing – Filtration of oils, syrups, juices, wine, and other food-grade liquids; ensures purity and compliance with hygiene standards.

- Oil and Gas – Removal of particulates, sludge, or sand from crude oil, natural gas, and process fluids.

- Water Treatment – Removal of suspended solids and fine particles in industrial water and wastewater treatment systems.

- High-Temperature Industrial Processes – Suitable for filtration in furnaces, heat exchangers, and hot fluid systems.

- Aerospace and Automotive – Precision filtration of fuels, lubricants, and hydraulic fluids in critical machinery.

- Heavy Industries – Metallurgy, ceramics, glass, and electronics requiring high-strength, corrosion-resistant, fine filtration.

Request A Quote

* indicates required fields