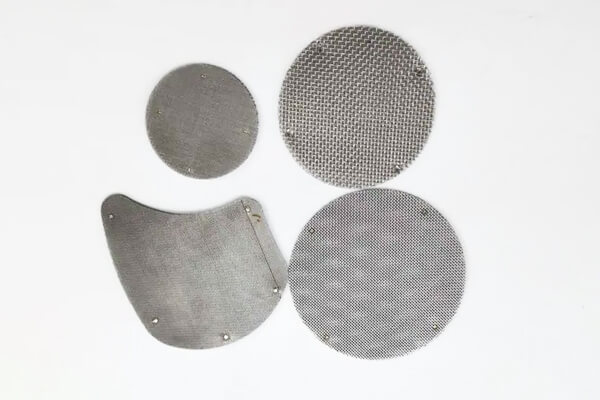

Filter Discs

HOME / MESH FILTER ELEMENTS / Filter Discs

Filter Discs Manufacturer | Wire Mesh, Sintered & Leaf Disc Filters | PFM SCREEN

Filter Discs are precision-engineered filtration components widely used in liquid and melt filtration systems across chemical processing, polymer extrusion, water treatment, pharmaceuticals, food & beverage, and many other industrial sectors. Manufactured from high-quality wire mesh and advanced sintered materials, filter discs are designed to remove solid impurities, gels, and contaminants, ensuring stable process performance, equipment protection, and consistent product quality.

PFM SCREEN Filter Discs are available in a wide range of structures, materials, and filtration ratings to meet diverse operating conditions such as high pressure, high temperature, corrosive media, and continuous operation. From simple single-layer wire mesh discs to complex pressure leaf and polymer melt leaf disc filters, we provide both standard and fully customized filtration solutions.

Filter Discs Product Options

To address different filtration mechanisms and process requirements, PFM SCREEN offers a complete portfolio of Filter Discs, including:

Wire Mesh Filter Disc

Manufactured from woven wire mesh, these discs offer economical and reliable surface filtration. They can be produced in single-layer or multi-layer configurations and cut into various shapes according to customer drawings.

Sintered Wire Mesh Filter Disc

Made by diffusion bonding multiple layers of wire mesh, sintered filter discs provide superior mechanical strength, stable pore structure, and excellent filtration accuracy, suitable for high-pressure and high-temperature environments.

Spot Welded Filter Disc

Constructed by spot welding multiple mesh layers together, these filter discs enhance rigidity and service life while maintaining good permeability, commonly used in hydraulic, fuel, and lubrication systems.

Framed Filter Disc

Also known as Encased Screen Discs or Edge-Bound Filter Discs, these products feature metal frames that reinforce the mesh edge, prevent bypass, and improve sealing performance during installation.

Pleated Filter Disc

Designed with a pleated structure to significantly increase effective filtration area, pleated filter discs offer higher dirt-holding capacity and longer service life in compact filtration systems.

Pressure Leaf Disc Filter

A high-capacity industrial filtration element used in pressure leaf filters, ideal for batch or continuous filtration of liquids with high solids content.

Polymer Melt Leaf Disc Filter

Specially developed for polymer melt filtration, these leaf disc filters withstand extreme temperatures and pressures, effectively removing gels and contaminants in extrusion and spinning processes.

Advantages of PFM SCREEN's Filter Discs

PFM SCREEN Filter Discs are engineered to deliver reliable, long-term filtration performance under demanding industrial conditions. Key advantages include:

- Wide Filtration Accuracy Range

Available from coarse filtration to micron-level precision, filter discs can be tailored to control particle retention, gel removal, and solid separation across multiple process stages. - Multiple Structural Designs

From single-layer woven mesh to multi-layer sintered constructions and pleated high-surface-area designs, PFM SCREEN filter discs adapt to both low-pressure and high-pressure filtration systems. - High Mechanical Strength & Dimensional Stability

Sintered, spot welded, and framed filter discs maintain structural integrity under high differential pressure, vibration, and thermal cycling without deformation or mesh migration. - Excellent Flow Rate with Low Pressure Drop

Optimized mesh layouts and pleated structures ensure high permeability, reduced clogging, and stable flow performance, improving overall system efficiency. - Resistance to Extreme Operating Conditions

Manufactured from stainless steel and specialty alloys, filter discs withstand high temperature polymer melts, corrosive chemicals, and aggressive cleaning processes. - Long Service Life & Reusability

Many filter disc types are designed for backflushing, cleaning, or regeneration, reducing replacement frequency and total operating costs. - Flexible Customization Capability

Diameter, thickness, filtration rating, mesh structure, frame design, and connection details can all be customized to fit specific housings or process requirements.

Applications of Filter Discs

PFM SCREEN Filter Discs are widely applied across industries where process reliability and product purity are critical:

- Polymer & Plastics Processing

Used in extrusion, spinning, and compounding lines for polymer melt filtration, removing gels, unmelted particles, and contaminants to protect downstream equipment. - Chemical & Petrochemical Industry

Applied in catalyst recovery, resin filtration, solvent purification, and chemical processing where high-temperature and corrosion resistance are essential. - Hydraulic, Fuel & Lubrication Systems

Filter discs provide reliable protection for pumps, valves, and precision components by removing solid particles from oils and fuels. - Water & Wastewater Treatment

Used in pre-filtration, fine filtration, and solids separation for industrial water treatment and municipal systems. - Pharmaceutical & Biotechnology

Precision filter discs support process filtration with consistent pore structure and cleanable metal materials suitable for controlled environments. - Food & Beverage Processing

Applied in syrup, beverage, edible oil, and process water filtration where durability and repeatable cleaning are required. - Pulp, Paper & Fiber Industry

Used in stock preparation, chemical recovery, and process water filtration to ensure stable production and equipment protection.

Why Choose PFM SCREEN's Filter Discs

PFM SCREEN is not just a filter disc supplier, but a long-term filtration solution partner for industrial customers worldwide.

- Specialized Filtration Manufacturer

With deep expertise in wire mesh and industrial filtration, we understand how mesh structure, bonding methods, and materials directly affect filtration performance. - Complete Product Portfolio

From standard wire mesh filter discs to advanced pressure leaf and polymer melt leaf disc filters, we provide one-stop sourcing for diverse filtration needs. - Strict Quality Control System

Each filter disc undergoes inspection for mesh accuracy, welding integrity, dimensional tolerance, and surface finish to ensure consistent quality. - Strong Custom Engineering Capability

We support OEM and project-based filtration solutions, working from drawings, samples, or application parameters to deliver optimized designs. - Proven Global Supply Experience

PFM SCREEN products are widely supplied to Europe, North America, and other international markets, meeting the expectations of industrial B2B customers. - Responsive Technical Support

Our team provides professional guidance on filter selection, performance optimization, and replacement planning to help reduce downtime and operational risk.