Extruder Screens & Polymer Filters

HOME / MESH FILTER ELEMENTS / Extruder Screens

Extruder Screens & Polymer Filters for Melt Filtration in Plastic & Rubber Processing

Extruder screens—also known as extrusion filter screens or melt filter screens—are precision woven wire mesh discs, packs, or screens installed inside an extruder to filter contaminants from molten plastic, rubber, and other polymer-based materials.

They play a critical role in ensuring melt purity, stabilizing extrusion pressure, and protecting key components such as the screw, breaker plate, and die.

In modern extrusion lines, extruder screens are considered indispensable filtration components, enabling manufacturers to achieve high-quality film, sheet, pipe, profile, and pellet products.

PFM SCREEN has over 20 years experience in manufacturing extruder screens and screen packs for the polymer and fiber industries. We offer standard and custom products, designed to meet the demanding requirements of the industry.

Extruder Screens & Polymer Filter Product Options

Beyond maintaining an extensive inventory of extruder screens in various sizes, shapes, mesh configurations, and materials for fast delivery, we also manufacture fully customized screens in-house. Our precision production capabilities ensure every screen meets your exact specifications for reliable fit, stability, and long-term performance.

Our extruder screens are engineered to suit a wide variety of screen changers and belt-type filtration systems.

PFM SCREEN’s product range includes:

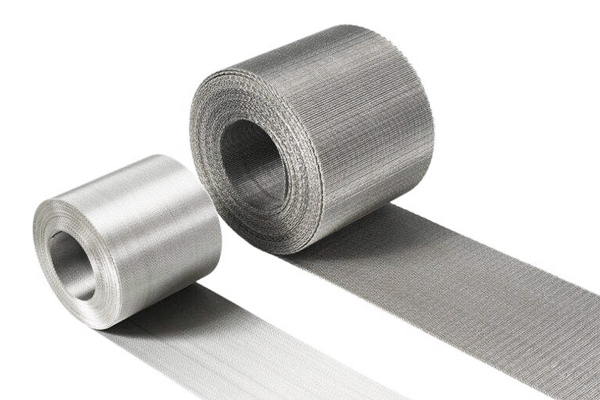

Continuous Filter Belts

Continuous filter belts provide uninterrupted melt filtration for high-output extrusion lines, delivering stable pressure, extended running time, and exceptional processing efficiency.

Welded Extruder Screen Packs

Welded screen packs combine multiple mesh layers spot-welded in sequence to ensure progressive filtration, high dirt-holding capacity, and consistent melt quality in demanding processes.

Frame Extruder Screen Packs

Frame extruder screen packs feature mesh securely fitted into a rigid aluminum frame, ensuring easy installation, perfect alignment, and superior stability under extrusion pressure.

Pleated Extruder Screen Packs

Pleated extruder screens increase the effective filtration area while minimizing pressure drop, offering longer service life and improved efficiency for fine-filtration extrusion applications.

Cylindrical Extruder Screens

PFM SCREEN specializes in manufacturing a full range of cylindrical filtration elements for extrusion applications. With numerous mesh configurations available, we provide solutions that deliver more uniform flow and reduced pressure drop.

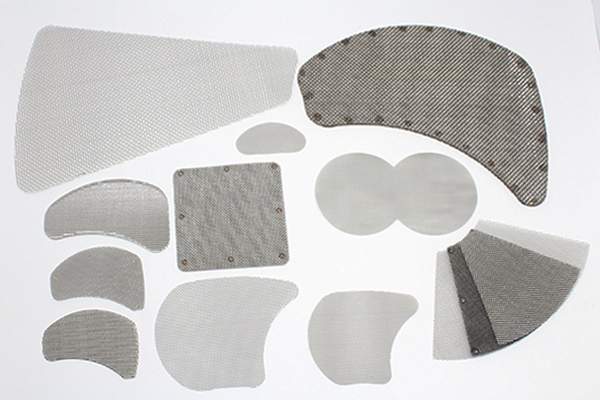

Special Shapes Extruder Screen

Special-shaped extruder screens are custom-engineered to meet unique equipment designs, ensuring precise fit, reliable filtration performance, and compatibility with specialized extrusion systems.

Advantages of PFM SCREEN's Extruder Screens

- Superior Contaminant Removal: Filters out foreign particles, carbonized materials, and gels to protect downstream equipment and ensure product integrity.

- Pressure Generation: Assists in developing consistent backpressure crucial for stable melt pumping and uniform output.

- Flow Homogenization: Straightens and aligns the polymer melt flow, eliminating irregularities for a consistent final product.

- Process Protection: Shields sensitive dies and other components from damage caused by hard contaminants.

- Versatility: Suitable for virgin resins, recycled materials, and high-viscosity polymers like PP, PE, PET, PVC, and more.

- High Filtration Precision: From 10 microns to 5000 microns to meet diverse production needs.

- Premium Materials: Stainless steel 304/316L, nickel alloys, brass, phosphor bronze, and other corrosion-resistant metals.

- Customizable Designs: Sizes, shapes, mesh counts, layers, ring/frame materials, pleated designs, and packaging options.

Why Choose PFM SCREEN Extruder Screens?

PFM SCREEN has grown into a trusted global supplier of industrial filtration solutions, particularly in polymer melt filtration, where precision, stability, and consistency determine product quality. Choosing PFM SCREEN means choosing a partner who understands your extrusion process at a technical level.

1. 20+ Years of Expertise in Polymer Filtration

With decades of experience serving film extrusion, pelletizing, compounding, masterbatch, fiber production, and recycling industries, we understand the filtration challenges faced by different polymers—from high-viscosity TPU/PA to shear-sensitive EVA & specialty resins.

2. Complete Extruder Screen Product Line

We provide a full range of products, allowing customers to source everything from one supplier:

- Continuous Screen Changer Belts

- Welded, Framed, Pleated, and Sintered Screen Packs

- Cylindrical and Candle Filter Elements

- Special-Shaped Screens for OEM equipment

- Whatever your extruder model or filtration unit, we can engineer a matching screen.

3. High-Precision Manufacturing & Quality Control

PFM SCREEN utilizes global-level production standards:

- Automatic spot-welding for uniform strength

- Strict mesh opening inspection (ASTM / ISO standard)

- Multi-layer alignment control

- Burr-free edges

- 100% visual inspection before packing

Each screen is manufactured for zero deformation and stable filtration accuracy under pressure.

4. Wide Material Options for Different Polymers

We supply all industry-standard alloys:

- SS304 / SS316L

- 202 / 430 stainless

- Brass / Phosphor Bronze

- Nickel, Monel, Inconel

- Duplex & specialty alloys

This ensures proper compatibility with corrosive melts, abrasive contaminants, or high-temperature production lines.

5. Competitive Price with Premium Quality

Thanks to efficient production and strict process control, PFM SCREEN achieves an excellent balance of:

- Better durability

- Longer filtration cycles

- More stable melt pressure

- Lower operating cost