Sintered Mesh Candle Filter

HOME / MESH FILTER ELEMENTS / Candle Filters / Sintered Mesh Candle Filter

Sintered Mesh Candle Filter | Stainless Steel Candle Filters | Multi-Layer Sintered Filter Elements

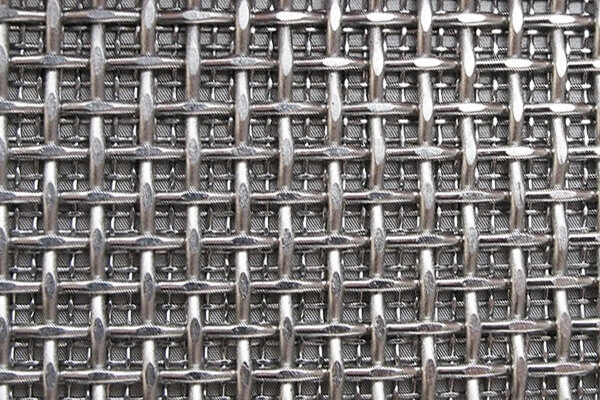

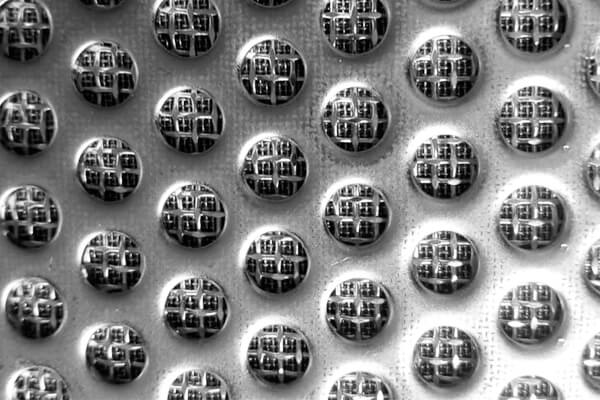

A Sintered Mesh Candle Filter is a high-precision filtration element made from multi-layer 304 or 316L stainless steel woven mesh, typically constructed with a 5-layer laminated structure and strengthened through vacuum sintering. This process permanently bonds each layer and forms a rigid, stable, and uniformly porous medium with excellent mechanical strength.

Thanks to its sintered construction, the filter delivers exceptional corrosion resistance, high-temperature stability, and a consistent micron rating that does not deform under pressure. Its smooth surface enables easy cleaning through backwashing or chemical cleaning, allowing repeated reuse and reducing operating cost.

The strong corrosion resistance not only removes corrosive particles and impurities from liquids or gases, but also protects pipes, pumps, valves, and downstream equipment, improving process reliability and reducing maintenance frequency in chemical and industrial systems.

To meet more demanding environments, filters can also be produced from Hastelloy, Monel, Inconel, titanium, and other specialty alloys, offering superior resistance to strong acids, alkalis, and high-temperature solvents.

Advantages of Sintered Mesh Candle Filter

1. High Mechanical Strength and Pressure Resistance

Sintered mesh is inherently strong due to the diffusion bonding of each metal wire. This ensures the filter element will not deform or collapse under high differential pressure, viscosity, or flow rates.

2. Accurate and Stable Filtration Performance

Thanks to its uniform pore structure, the sintered mesh ensures consistent and repeatable micron-level precision, improving product purity and process stability.

3. Excellent Backwash and Reusability

Sintered mesh candle filters can be cleaned using several methods:

- Reverse flow backwashing

- Ultrasonic cleaning

- Chemical cleaning (acid/alkali compatible)

This reduces operating cost significantly compared to disposable filtration elements.

4. Outstanding Temperature and Corrosion Resistance

Alloys like stainless steel, Hastelloy, and Inconel allow these filters to withstand aggressive chemicals and extreme temperatures, making them suitable for harsh production environments.

5. Large Filtration Area in Compact Space

The candle shape maximizes the surface area, enabling high flow rates and longer operating cycles before cleaning is required.

6. Long Service Life & Cost Savings

Because of their durability and reusability, sintered mesh candle filters provide excellent long-term economic value.

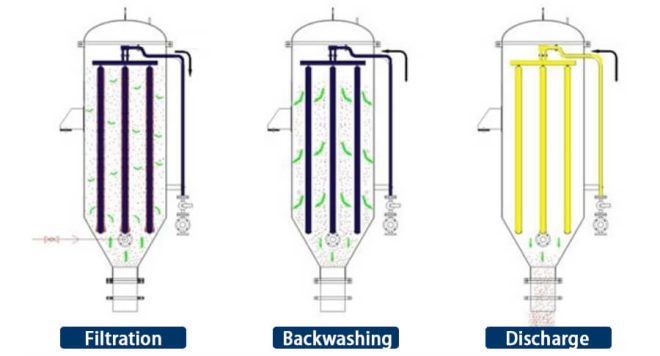

How Sintered Mesh Candle Filters Work

The filtration mechanism relies on the multi-layer pore structure, where each layer provides a different function:

- The protective layer prevents damage to the filtration layer

- The control layer determines the final filtration precision

- The support layer provides mechanical strength

- Additional layers improve drainage or protect against backwashing stress

As fluid flows through the candle filter, contaminants are trapped on the outer surface or within the porous structure. During backwashing, the flow is reversed to dislodge and remove trapped particles, restoring the filter’s capacity.

Sintered Mesh Types of Sintered Mesh Candle Filter

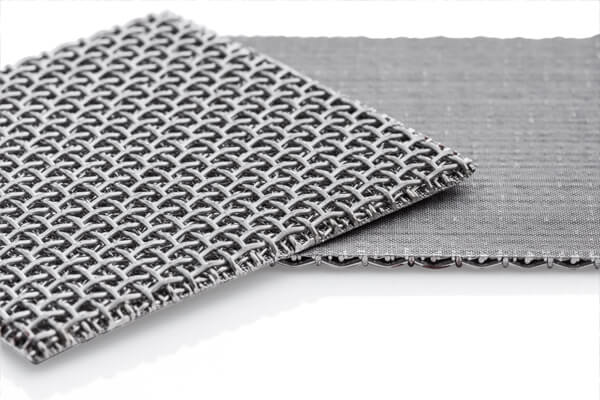

Multiple Layer Sintered Mesh

Multiple layer sintered mesh combines two or more layers of woven mesh through a vacuum sintering process to form a strong, durable, and uniformly porous structure. Each layer plays a specific role—filtration, support, protection—resulting in higher strength, stable micron accuracy, and excellent resistance to deformation under pressure.

Five-Layer Sintered Mesh

Five-layer sintered mesh is the industry-standard structure for high-performance candle filters. It typically includes a protective layer, precision filter layer, control layer, and two supporting layers. This design ensures precise and repeatable filtration, high mechanical strength, excellent permeability, and long service life, making it ideal for polymer melt and chemical filtration.

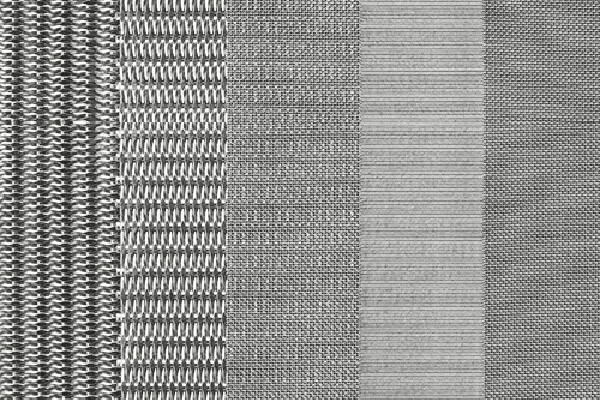

Plain Sintered Square Weave Mesh

Plain sintered square weave mesh is made by sintering square-woven mesh layers into a stable laminate with a larger open area. It provides high flow rates, low pressure drop, and strong backwash performance. This mesh type is suitable for liquid filtration processes where high throughput and moderate filtration accuracy are required.

Sintered Dutch Weave Mesh

Sintered Dutch weave mesh features a fine filtration layer made from Dutch weave wire mesh combined with supporting layers through sintering. It offers ultra-precise micron ratings, high dirt-holding capacity, and strong structural integrity. It is ideal for fine particle retention in catalyst recovery, chemical processing, and gas purification.

Perforated Metal Sintered Wire Mesh

Perforated metal sintered wire mesh is a composite structure in which woven mesh is sintered onto a perforated metal plate. The perforated layer provides maximum rigidity, excellent impact resistance, and strong support for large candle filters. It is widely used in high-pressure, high-flow, or mechanically demanding filtration environments.

Connection Types of Sintered Mesh Candle Filter

Sintered mesh candle filters can be equipped with a wide range of connection types to ensure compatibility with different housings, filtration systems, and industrial pipelines. The following are the most common connector options available:

Specifications of Sintered Mesh Candle Filter

Design

- Smooth

- Pleated

Available Materials

- SS304 / SS316L

- Duplex steel

- Hastelloy C276

- Monel 400

- Inconel 600 / 625

- Titanium

- Nickel alloys

Micron Rating

- 1–200 μm, stable and repeatable.

Operating Conditions

- Temperature: up to 480°C (varies by alloy)

- Max differential pressure: customized depending on mesh structure

Dimensions

- Diameter: 25–160 mm

- Length: 100–1500 mm

- Filtration area: varies for cylindrical or pleated design

- Custom sizes accepted

Applications of Sintered Mesh Candle Filter

Sintered Mesh Candle Filters are widely used across demanding industries:

Polymer & Plastic Extrusion

- Polyester, nylon, PP, PE, PET pellets

- Melt filtration systems

- Continuous polymer production lines

Chemical & Petrochemical Processing

- Catalyst recovery

- High-viscosity fluid filtration

- Solvent purification

Oil & Gas

- Natural gas filtration

- Produced water filtration

- Wellhead filtration

Food & Beverage

- Syrup & sugar filtration

- Cooking oil purification

- Brewing and fermentation processing

Water & Waste Treatment

- Pre-filtering & polishing filtration

- High flow rate liquid filtration

Request A Quote

* indicates required fields