Candle Filters

HOME / MESH FILTER ELEMENTS / Candle Filters

Candle Filters | Pleated, Sintered Mesh & Porous Metal Filters

Candle Filters are precision filtration elements widely used in liquid and gas purification processes across industries such as chemicals, polymers, petrochemicals, pharmaceuticals, food processing, and environmental treatment. Unlike disposable filter cartridges made from paper or synthetic fibers, metal Candle Filters deliver long service life, stable filtration efficiency, and excellent resistance to high temperatures, corrosion, and pressure.

A Candle Filter typically consists of a cylindrical filter body made from stainless steel or other high-grade alloys. Through pleated mesh, sintered mesh laminates, or sintered porous metal structures, these elements provide controlled filtration ratings ranging from 1 micron to 200 microns. Many systems use Candle Filters in backwashing or blowback-cleaning filtration units, ensuring efficient regeneration and reduced downtime.

PFM SCREEN offers a full range of Pleated Candle Filters, Sintered Mesh Candle Filters, and Sintered Porous Candle Filters, all designed for demanding industrial filtration applications.

Candle Filter Product Options

PFM SCREEN offers multiple types of metal Candle Filters—Pleated Candle Filters, Sintered Mesh Candle Filters, and Sintered Porous Candle Filters—each engineered to meet different filtration performance needs, operating environments, and regeneration methods. Whether your process requires high flow capacity, precise micron control, or extreme temperature and pressure resistance, these filter options ensure optimal efficiency and long-term durability across a wide range of industrial applications.

Pleated Candle Filter

Pleated Candle Filters are produced by pleating woven wire mesh to create a large filtration area within a compact structure. The pleated design significantly increases dirt-holding capacity while maintaining a low pressure drop.

Sintered Mesh Candle Filter

Sintered Mesh Candle Filters are manufactured using multi-layer sintered stainless steel wire mesh, delivering mechanical strength, precise filtration rating, and excellent backwash performance.

Sintered Porous Candle Filter

Sintered Porous Candle Filters are made from sintered metal powder (stainless steel, Inconel, Monel, Hastelloy, titanium). Their porous structure offers deep filtration, high dirt-holding capacity, and long service life in severe operating conditions.

Advantages of PFM SCREEN's Candle Filters

PFM SCREEN specializes in manufacturing high-performance metal Candle Filters with advantages including:

1. Durable All-Metal Construction

- Stainless steel, Duplex, Inconel, Monel, and Hastelloy alloys

- High corrosion, pressure, and temperature resistance

2. Fully Cleanable and Reusable

- Backwashable designs reduce operating costs and waste

- Long service life compared with fiber or paper cartridges

3. Precision Filtration

- Accurate and stable filtration ratings from 0.2 to 200 microns

- Consistent pore size and uniform flow distribution

4. Enhanced Mechanical Strength

- Support cores and multi-layer structures resist deformation under pressure

5. Custom Engineering

- Complete flexibility in dimensions, pleat depth, mesh layers, and alloy grades

- Tailored for customer-specific flow, pressure, and filtration efficiency requirements

Why Choose PFM SCREEN Candle Filters?

PFM SCREEN is a leading metal mesh filtration manufacturer with extensive expertise in industrial Candle Filter design and production. Customers choose PFM SCREEN because:

1. Industry-Grade Quality Control

- Full inspections on mesh material, sintering quality, pore size uniformity, pressure resistance, and welding accuracy

- ISO production standards and batch traceability

2. Professional Engineering Support

- Technical consultation for system design, filter selection, and operational optimization

- CAD drawings, flow calculations, and replacement solutions

3. High Customization Capability

- Tailored dimensions, filtration ratings, pleat counts, alloys, and connection types

- OEM and ODM services for global filtration equipment manufacturers

4. Reliable Global Supply

- Stable production, large inventory of stainless steel mesh and sintered materials

- Fast delivery for standard and custom Candle Filters

- Strong capability in serving European, Middle Eastern, and Asian markets

5. Proven Performance in Harsh Applications

- Hot gas filtration above 750°C

- Polymer melt filtration

- Chemical and petrochemical processes

- High-viscosity fluid and catalyst recovery

PFM SCREEN Candle Filters offer consistent performance, long service life, and superior mechanical integrity, making them a trusted solution in demanding industrial environments.

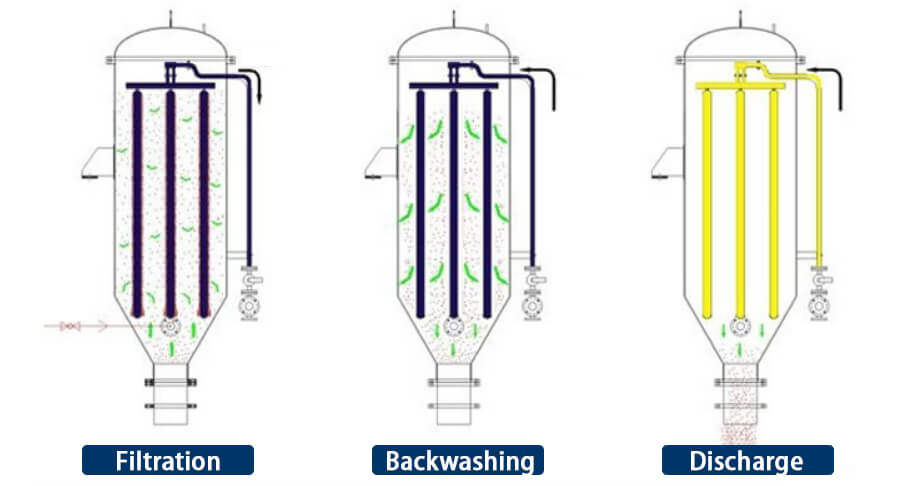

How Candle Filters Work

Candle Filters operate based on surface filtration or depth filtration, depending on their construction:

1. Filtration Stage

- Contaminants are captured on the outer surface (pleated or sintered mesh) or within the inner porous structure (sintered powder).

- Clean fluid flows through the filter media toward the inner support and exits through the clean outlet.

2. Cake Formation

- In many applications, solids build up on the filter surface forming a “filter cake.”

- This cake layer further enhances fine particle capture and increases filtration efficiency.

3. Cleaning / Regeneration

Most metal Candle Filters can be regenerated using:

- Backwashing / reverse flow

- Blowback with compressed gas

- Ultrasonic cleaning

- Chemical cleaning depending on contaminants

This enables continuous or semi-continuous operation, reducing replacement costs.