Knitted Mesh

HOME / SCREEN MESH MATERIALS / Knitted Mesh

Knitted Mesh | Stainless Steel, Copper & Alloy Knitted Wire Mesh Manufacturer

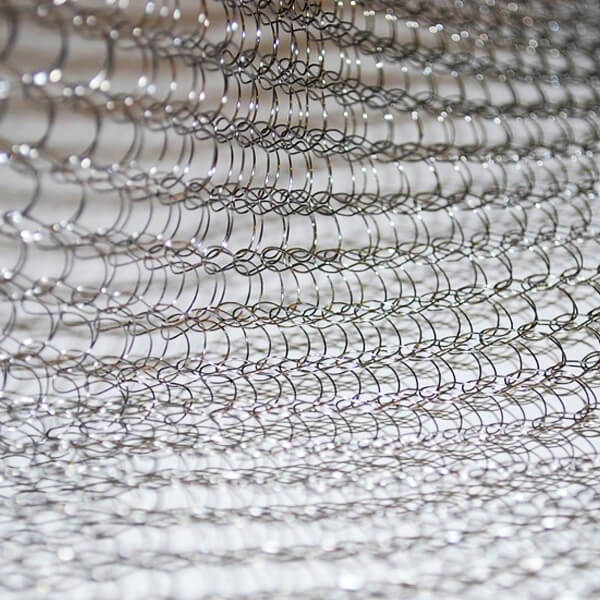

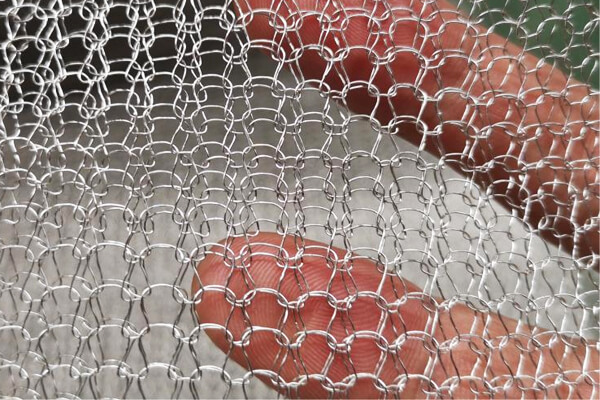

Knitted mesh is made using specialized knitting machines that loop metal wires into a flexible, porous, and three-dimensional structure. Unlike woven wire mesh, knitted mesh can be compressed, layered, rolled, crimped, or molded into various shapes—making it ideal for applications that require high resilience, vibration damping, filtration depth, and controlled compressibility.

Benefits of Knitted Mesh

Knitted Mesh provides advantages not found in woven or expanded metal mesh:

- Exceptional Flexibility & Formability

Can be shaped into cylinders, pads, rings, rolls, tapes, or custom molded parts. - Superior Filtration & Separation Efficiency

Multi-layer structures provide outstanding liquid–gas and solid–liquid separation properties. - High Durability Under Extreme Conditions

Suitable for environments involving high temperatures, corrosive media, pressure fluctuations, and mechanical stress. - Vibration Damping & Noise Reduction

Widely used as sound-absorbing and shock-absorbing components in automotive and aerospace engineering. - Wide Range of Material Options

Different metals offer unique performance benefits—stainless steel for corrosion resistance, copper for conductivity, and alloys for temperature or chemical resilience.

Typical Applications of Knitted Mesh

Knitted mesh is highly adaptable and used across many industries:

- Mist Eliminators / Demister Pads

Captures fine mist & droplets in petrochemical towers. - Industrial Filtration & Separation

Used in liquid–gas, gas–gas, and liquid–liquid separation. - EMI/RFI Shielding

Copper and stainless steel knitted mesh used in electronic enclosures. - Automotive Exhaust & Noise Reduction

Heat-resistant knitted mesh used in mufflers, exhaust components, and vibration dampers. - Gaskets, Seals & Packing

Formed mesh provides resilience and pressure resistance. - Catalyst Support & Chemical Processing

Alloy knitted mesh works in high-temperature catalytic reactors. - Flame Arresters & Spark Arresters

Metal mesh absorbs heat and prevents flame propagation.

Knitted Mesh Product Types in This Category

This parent page covers the three primary material-based knitted mesh products:

Stainless Steel Knitted Mesh

Made from SS304, SS316, SS316L, and other grades. Ideal for mist eliminators, demister pads, filtration, EMI shielding, and industrial sealing.

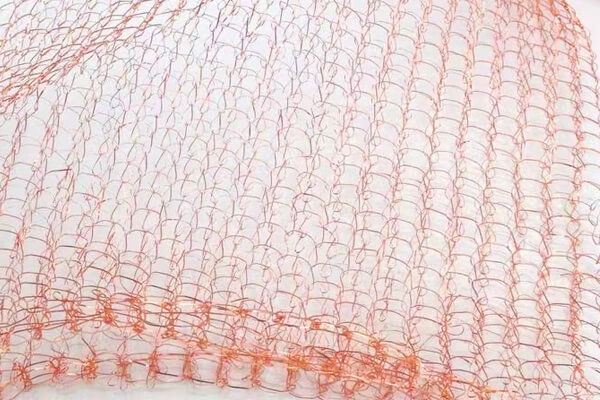

Copper Knitted Mesh

Excellent electrical and thermal conductivity. Commonly used in EMI/RFI shielding, grounding, distillation, chemical filtration, and spark arresting.

Alloy Metal Knitted Mesh

Includes Inconel, Monel, Nickel, Hastelloy, FeCrAl, etc. Suitable for high-temperature reactors, corrosive chemical processing, aerospace components, and specialty filtration systems.

Why Choose Our Knitted Mesh Products?

- Advanced Knitting Equipment

Precision knitting ensures stable pore structure and consistent performance. - Wide Material Selection

From stainless steels to nickel-based alloys and copper—customizable for your application. - Custom Shapes & Densities

Rolls, pads, cylinders, rings, tapes, gaskets, and multi-layer compressed structures. - Strict Quality Control

Dimensional accuracy, mechanical strength, and filtration performance tested on every batch. - Global Supply for Industrial Users

Serving filtration, petrochemical, power generation, automotive, and environmental markets worldwide.