Sintered Mesh

HOME / SCREEN MESH MATERIALS / Sintered Mesh

Sintered Mesh – High-Performance Diffusion-Bonded Metal Filter Media

Sintered mesh is a high-performance metal filter material produced by bonding one or multiple layers of woven wire mesh through a precise sintering process. During this process, layers of wire mesh are first flattened and then stacked together under controlled mechanical pressure inside a high-temperature furnace filled with protective gas. The metal wires are heated to a temperature below their melting point, allowing them to fuse permanently at their contact points through solid-state diffusion. This forms a strong, stable, and porous metallic structure with excellent mechanical integrity.

Depending on specific filtration requirements, sintered mesh can consist of a single layer or multiple layers combined into a composite laminate. Typically, a fine filtration layer is supported by one or more coarse meshes or even a perforated metal sheet to enhance overall strength and durability. The result is a robust filter medium with uniform pore size distribution, high permeability, and exceptional pressure resistance.

Thanks to its rigid structure, sintered mesh can be easily fabricated into various shapes and components such as filter discs, plates, cartridges, and conical filters. It offers superior advantages over traditional woven wire mesh filters, including:

- High mechanical strength and rigidity

- Excellent permeability with low pressure drop

- Precise and consistent filtration accuracy

- Good corrosion and temperature resistance

- Easy cleaning and long service life

Sintered mesh filters are widely used in demanding industrial applications, including chemical processing, petrochemical systems, polymer filtration, water treatment, and hydraulic equipment. Their ability to withstand repeated cleaning and backwashing makes them a cost-effective choice for continuous and long-term filtration operations.

Although primarily designed for technical applications, sintered metal meshes can also serve special architectural or design purposes—such as acoustic panels or light-diffusing surfaces—where a metallic, textured, and durable material is desired.

Sintered Mesh Product Classification By Layer Structure

At PFM SCREEN, our sintered wire mesh is produced with permanently fused, non-fraying weaves and offered in a wide range of widths, thicknesses, and micron ratings. Customers can select from one-, two-, three-, or five-layer constructions. The mesh can also be fabricated into customized forms such as sheets, panels, or filter discs to suit specific application needs.

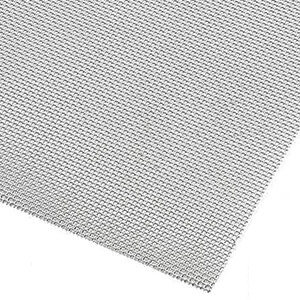

Single Layer Sintered Mesh

Single-layer sintered mesh is made from one sheet of woven wire mesh that has been sintered for enhanced stability and rigidity. This type features a simple structure and is mainly used for coarse filtration, flow distribution, or as a support layer in composite filter systems. It offers good permeability, uniform pore size, and can be easily formed into discs, plates, or cylinders for various industrial applications.

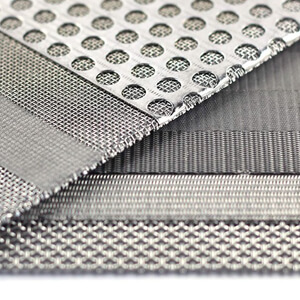

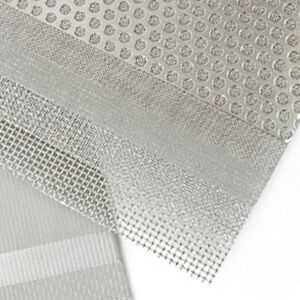

Multi-Layer Sintered Mesh

Multi-layer sintered mesh consists of several layers of woven wire mesh sintered together to create a durable, integrated filter medium. The most common configuration includes five layers—protection, dispersion, fine filtration, support, and reinforcing layers. This design ensures high mechanical strength, uniform filtration precision, and excellent backwash performance, making it ideal for demanding industrial filtration processes.

Five-Layer Sintered Mesh (Standard Type)

The five-layer sintered mesh is the standard and most widely used structure in industrial filtration. It combines optimal permeability with strong mechanical support. The fine mesh layer provides accurate filtration, while the coarse and reinforcing layers ensure structural stability under high pressure. This type is widely used in chemical, polymer, and hydraulic systems for precise and stable filtration.

Sintered Mesh Product Classification By Mesh Type

PFM SCREEN provides a comprehensive range of sintered wire mesh products classified by mesh type, including Plain Sintered Square Weave Mesh, Sintered Dutch Weave Mesh, and Perforated Metal Sintered Wire Mesh.

Each type of sintered mesh offers unique structural characteristics and performance advantages, meeting the filtration, separation, and reinforcement needs of different industries.

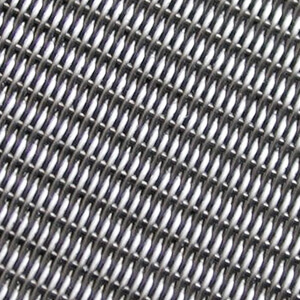

Plain Sintered Square Weave Mesh

Plain sintered square weave mesh is made from standard plain-woven wire cloth that has been sintered to form a strong, stable, and non-fraying structure. This type offers uniform pore size distribution, high permeability, and excellent mechanical strength. It is widely used in liquid and gas filtration, fluidization, and drying applications where consistent flow and reliable filtration performance are required. The square weave structure ensures precise control over micron ratings and easy cleaning or backflushing.

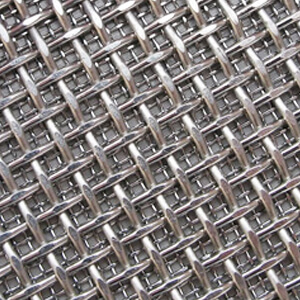

Sintered Dutch Weave Mesh

Sintered Dutch weave mesh combines fine filtration precision with exceptional strength and stability. It is made by sintering Dutch woven wire mesh layers—where fine wires are tightly woven in one direction and coarser wires in the other—to create a dense, high-strength filter medium. This structure provides superior particle retention, low pressure drop, and good backwash capability. It is ideal for polymer filtration, hydraulic systems, and chemical processing where high filtration accuracy and durability are essential.

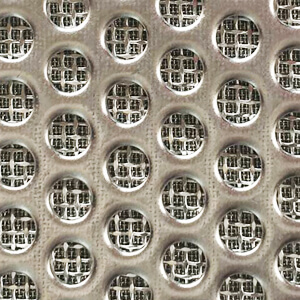

Perforated Metal Sintered Wire Mesh

Perforated metal sintered wire mesh consists of one or more layers of woven wire mesh sintered onto a perforated metal plate. The perforated plate provides excellent mechanical support and rigidity, while the wire mesh layers ensure precise filtration. This composite structure is suitable for high-pressure and heavy-duty filtration environments, such as oil and gas processing, petrochemical filtration, and polymer extrusion. The reinforced base allows for larger sizes and higher load capacity without compromising filtration performance.

Why Choose PFM SCREEN Sintered Mesh

Advanced vacuum sintering technology ensuring stable bonding

Wide range of mesh types and layer configurations

High corrosion resistance and mechanical strength

Precise filtration control with excellent backwash performance

Custom fabrication available for discs, cartridges, and panels