Screen Mesh Materials

Overview

PFM SCREEN offers a complete range of high-performance screen mesh materials engineered for filtration, separation, screening, and fluid control across demanding industrial environments. With decades of manufacturing experience and in-house processing capabilities, we supply precision mesh solutions tailored to mechanical strength, filtration accuracy, corrosion resistance, and long service life.

Our screen mesh materials are widely used in chemical processing, polymer filtration, water treatment, mining, food & beverage, pharmaceuticals, energy, and metallurgy, meeting both standard and custom application requirements.

Products

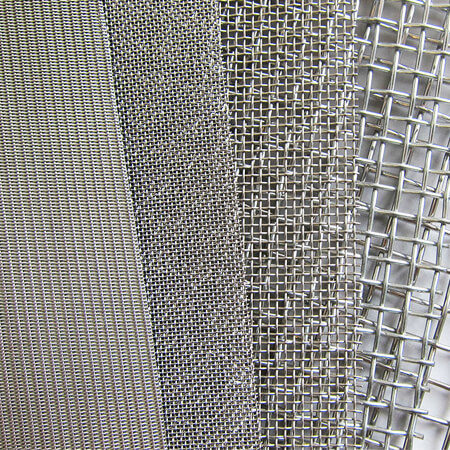

Woven Wire Mesh

Woven wire mesh is manufactured by interweaving metal wires in specific patterns to achieve precise and uniform openings. It offers excellent dimensional stability and a wide filtration range.

- Available weave types: Plain, Twill, Dutch, Reverse Dutch

- Materials: Stainless steel, carbon steel, brass, copper, nickel alloys

- Features: Accurate mesh openings, high tensile strength, good cleanability

- Typical applications: Filter discs, sieving, particle separation, screen panels

Sintered Mesh

Sintered mesh is produced by bonding multiple layers of woven wire mesh under high temperature and pressure, forming a rigid, integrated structure.

- Multi-layer or five-layer constructions available

- High mechanical strength and excellent pore stability

- Superior resistance to pressure and backflushing

- Ideal for high-precision and high-pressure filtration systems

- Common uses: Polymer melt filtration, hydraulic systems, fine chemical filtration

Sintered Felt

Sintered metal felt is made from randomly oriented metal fibers sintered together to create a three-dimensional porous structure.

- High porosity and dirt-holding capacity

- Uniform permeability and low pressure drop

- Excellent performance at high temperatures

- Materials include stainless steel and specialty alloys

- Applications: Gas filtration, catalyst recovery, fine dust filtration, aerospace and chemical industries

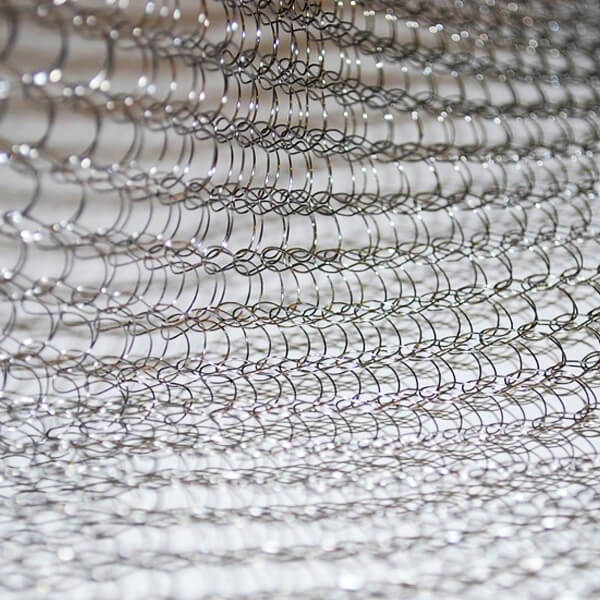

Knitted Mesh

Knitted mesh is formed by looping metal wires into an interconnected structure, offering high flexibility and energy absorption.

- High elasticity and shock absorption

- Excellent demisting and separation efficiency

- Custom densities and wire diameters available

- Widely used as mist eliminators, gas-liquid separators, EMI shielding

- Suitable for petrochemical and environmental applications

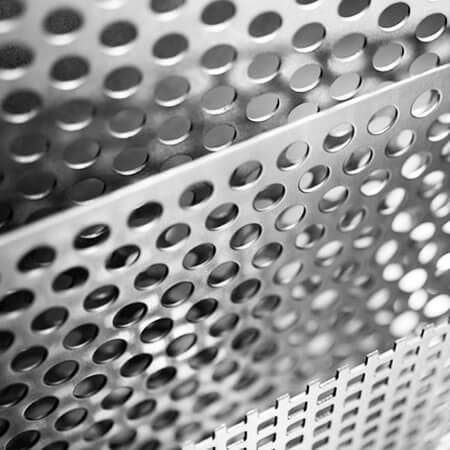

Perforated Metal

Perforated metal sheets are produced by punching precise hole patterns into metal plates, combining strength with controlled open area.

- Hole shapes: Round, square, slot, custom designs

- High load-bearing capacity and structural rigidity

- Easy to fabricate, weld, and form

- Applications include screening, guarding, ventilation, filtration support plates, architectural use

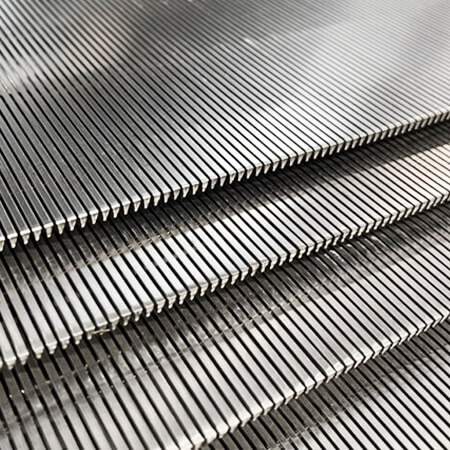

Wedge Wire Screen

Wedge wire screens are constructed by welding V-shaped profile wires onto support rods, creating continuous slot openings that resist clogging.

- Precise slot control and self-cleaning design

- High structural strength and abrasion resistance

- Excellent flow efficiency and low pressure loss

- Common materials: Stainless steel and alloy steels

- Applications: Water intake screens, well screens, rotary drum screens, resin traps, solid-liquid separation systems

Key Advantages of PFM SCREEN Mesh Materials

- Wide Material Selection – From fine filtration meshes to heavy-duty structural screens

- Precision Manufacturing – Tight tolerances and consistent quality

- Custom Engineering – Tailored mesh sizes, shapes, layers, and assemblies

- Durability – Designed for corrosive, high-temperature, and high-pressure environments

- Global Standards – Suitable for international and European industrial requirements

Industries & Applications

PFM SCREEN mesh materials are extensively used in:

- Industrial filtration and separation systems

- Polymer melt and extrusion filtration

- Water and wastewater treatment

- Oil & gas and petrochemical processing

- Food, beverage, and pharmaceutical production

- Mining, metallurgy, and power generation