Polymer Melt Leaf Disc Filters

HOME / MESH FILTER ELEMENTS / Filter Discs / Polymer Melt Leaf Disc Filter

Polymer Melt Leaf Disc Filter | Pressure Leaf Disc Filter for Polymer Filtration

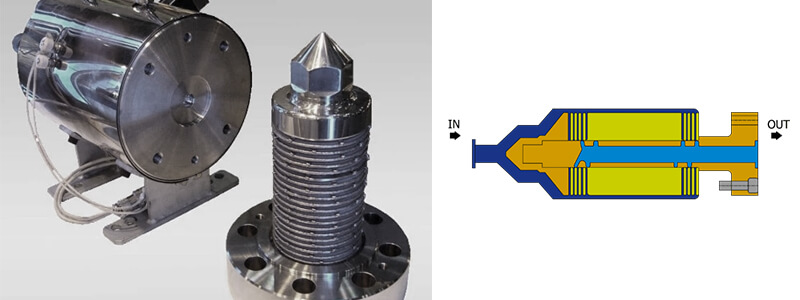

Polymer Melt Leaf Disc Filters are ultra-high-pressure filtration components specifically engineered for the synthetic fiber, film, and resin production industries. In the demanding environment of plastic extrusion, these discs remove microscopic impurities, carbonized particles, and—most critically—deformable gels from the molten polymer stream.

Unlike standard liquid filters, Polymer Melt Discs are designed to operate under extreme rheological conditions. By stacking these discs on a central mandrel, manufacturers achieve a massive filtration surface area within a compact housing, ensuring consistent melt quality, protecting downstream spinnerets, and minimizing thermal degradation of the polymer.

Structure & Design Features of Polymer Melt Leaf Disc Filter

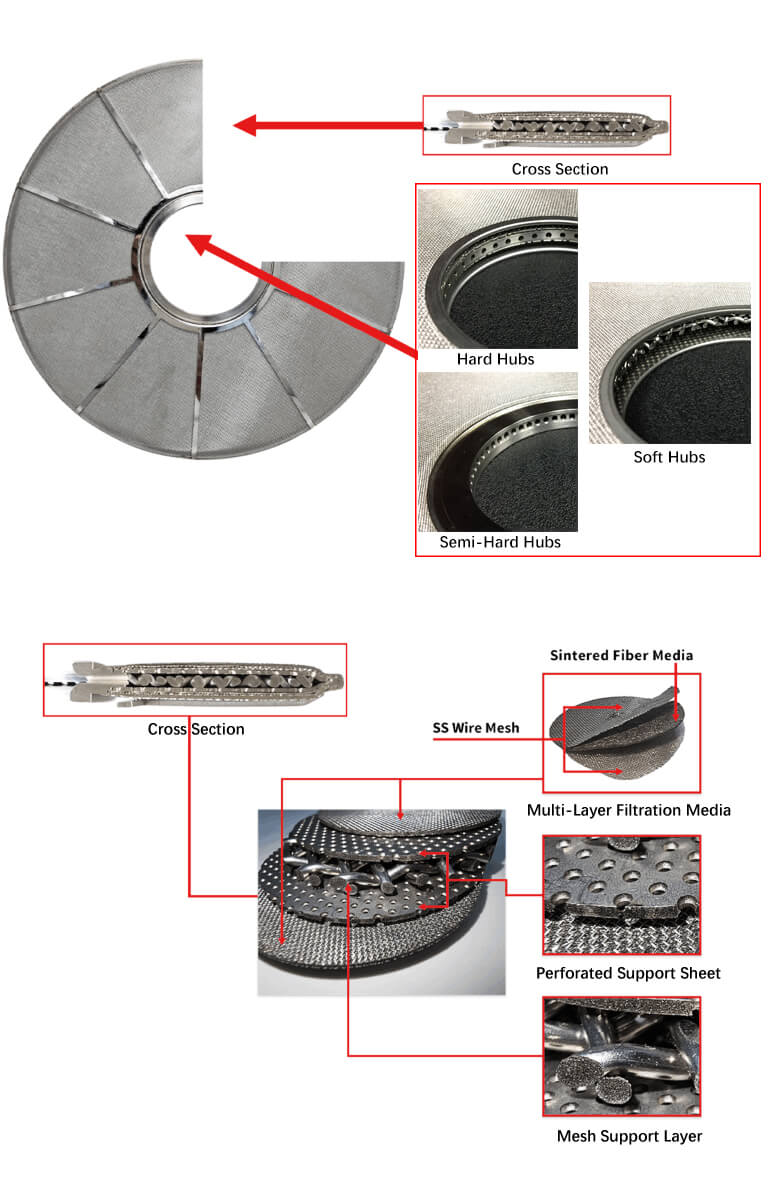

Our Leaf Disc Filters are engineered using a sophisticated multi-layer architecture, combining mechanical rigidity with high-precision filtration. Each component is selected to optimize the balance between dirt-holding capacity and structural integrity under extreme conditions.

To survive pressures exceeding 300 Bar, our Polymer Melt Leaf Discs feature a specialized multi-component architecture:

1. Advanced Multi-Layer Filtration Media

The core of the disc consists of Sintered Stainless Steel Wire Mesh or Sintered Metal Fiber Felt.

- Precision Performance: The diffusion-bonded layers provide absolute micron ratings and exceptional durability.

- Optimized Flow: This layered structure allows for ultra-fine filtration without sacrificing flow velocity, significantly reducing the rate of pressure increase (clogging).

- Enhanced Backwash/Cleaning: The sintered bond prevents pore migration, making the media highly responsive to ultrasonic and thermal cleaning.

2. Integrated Drainage & Support System

To prevent the filtration media from collapsing under high-viscosity melt flow, we incorporate a dual-support structure:

- Mesh Support Layer: Ensures the overall stability of the mesh pack and maintains the geometric integrity of the filtration pores.

- Perforated Support Sheet: A high-strength internal plate that acts as the primary “spine.” It allows filtered fluid to pass freely through precision-engineered openings while providing the rigidity needed to withstand differential pressures up to 15 MPa.

3. Specialized Central Hub Options

The central hub is the critical interface between the disc and the filter manifold. We offer three distinct hub designs to match your specific hardware and sealing requirements:

- Hard Hubs: Designed for metal-to-metal sealing in high-pressure stacks where precise spacing and zero compression are required.

- Semi-Hard Hubs: Provide a balance of structural rigidity with a slight seating capability for improved sealing in aging manifolds.

- Soft Hubs: Engineered for applications requiring superior sealing performance, where the hub conforms slightly to the manifold surface to prevent bypass.

Working Principle of Polymer Melt Leaf Disc Filter

The Polymer Melt Leaf Disc Filter operates under the principle of pressure-driven surface filtration.

- Molten polymer enters the filter housing under controlled pressure.

- The melt flows from the outside to the inside of the leaf disc filter elements.

- Solid contaminants are retained on the outer surface of the filter discs.

- Clean polymer melt passes through the precision filter media and exits through the central outlet.

- Accumulated impurities form a filter cake, enhancing fine filtration over time.

- When pressure drop reaches a preset value, the system can be cleaned, backflushed, or replaced, depending on process design.

This pressure leaf filtration mechanism ensures stable melt flow, minimal pressure fluctuation, and high contaminant removal efficiency, even under high-viscosity conditions.

Advantages of Polymer Melt Leaf Disc Filter

Key Benefits of Polymer Melt Pressure Leaf Disc Filters

- High Filtration Efficiency

Large effective filtration area ensures excellent contaminant retention. - Low Pressure Drop

Optimized disc geometry reduces flow resistance compared to traditional screen packs. - Extended Service Life

Robust metal filter media withstand high temperature, pressure, and chemical exposure. - Excellent Dirt-Holding Capacity

Capable of handling high impurity loads in recycled or filled polymers. - Stable Melt Quality

Reduces gels, black specks, and unmelted particles in final products. - Reduced Downtime

Longer filtration cycles mean fewer shutdowns and screen changes. - Customizable Design

Compatible with various polymer types, viscosities, and production capacities. - Cost-Effective Operation

Lower maintenance frequency and improved production yield.

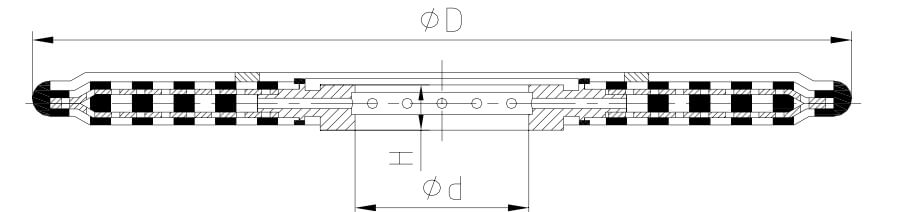

Specification of Polymer Melt Leaf Disc Filter

| Parameter | Technical Data |

| Filter Media | Sintered Metal Fiber (Felt) or Sintered Wire Mesh |

| Micron Rating | 3 µm to 100 µm (Absolute) |

| Max Operating Pressure | 31.5 MPa (315 Bar / 4500+ PSI) |

| Max Differential Pressure | Up to 15 MPa (150 Bar) |

| Max Temperature | 400°C (Standard) / 550°C (High-Temp Alloy) |

| Material | SS316L, SS304, Hastelloy C276 |

| Disc Configuration | Hard Hub, Soft Hub, or Semi-Hard Hub |

| Standard Diameters | 6″, 7″, 10″, 12″ (Custom sizes available) |

| Specification of Polymer Leaf Disc Filters | |||||

| Model | O.D. (inche) | O.D. (mm) | I.D. (mm) | Thickness (mm) | Filter Area (m2) |

| PFM-PMLF-6-38.2 | 6 | 152 | 38.2 | 6.5 | 0.032 |

| PFM-PMLF-7-38.2 | 7 | 178 | 38.2 | 6.5 | 0.048 |

| PFM-PMLF-7-47.6 | 7 | 178 | 47.6 | 6.5 | 0.046 |

| PFM-PMLF-7-63.5 | 7 | 178 | 63.5 | 6.5 | 0.044 |

| PFM-PMLF-7-85 | 7 | 178 | 85 | 6.5 | 0.038 |

| PFM-PMLF-10-47.6 | 10 | 254 | 47.6 | 7.2 | 0.082 |

| PFM-PMLF-10-85 | 10 | 254 | 85 | 6.5 | 0.08 |

| PFM-PMLF-12-63.5 | 12 | 305 | 63.5 | 6.5 | 0.13 |

| PFM-PMLF-12-85 | 12 | 305 | 85 | 6.5 | 0.12 |

| PFM-PMLF-12-85 | 12 | 305 | 85 | 7 | 0.12 |

| PFM-PMLF-12-85 | 12 | 305 | 85 | 7.5 | 0.12 |

Applications of Polymer Melt Leaf Disc Filter

Polymer Melt Leaf Disc Filters are essential for:

- Synthetic Fiber Spinning: Production of PET, PA6, PA66, and PP fibers (POY, FDY, Staple Fiber).

- Film Extrusion: High-quality optical films, BOPP, and BOPET packaging films.

- Polymer Manufacturing: Continuous filtration in polymerization plants for resin pelletizing.

- Advanced Recycling: Fine filtration of recycled PET (rPET) to remove residual contaminants and improve melt purity.

- Masterbatch Production: Ensuring pigment dispersion and removing agglomerates in high-concentrate additives.

Request A Quote

* indicates required fields