Coanda Intake Screen and Box

HOME / MESH FILTER ELEMENTS / Wedge Wire Screen Filters and Components / Coanda Intake Screen and Box

Coanda Intake Screen | Coanda Intake Boxes| Self-Cleaning Wedge Wire Water Intake Screen

The Coanda Intake Screen, also known as a self-cleaning wedge wire intake screen, is a high-efficiency water intake protection system designed to prevent debris, sediment, fish, and aquatic organisms from entering pumping systems and pipelines.

By combining precision wedge wire screen panels with the Coanda Effect, this intake solution delivers continuous, non-clogging operation without moving parts, mechanical cleaners, or external power.

Coanda Intake Screens and Coanda Intake Boxes are widely used in river intakes, canals, reservoirs, irrigation systems, hydropower plants, municipal water supply, industrial process water intakes, and environmentally sensitive projects, where reliability, low maintenance, and fish protection are essential.

Types

Coanda Intake Screens

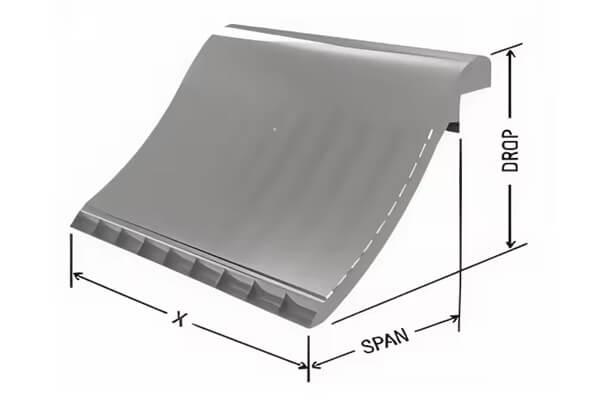

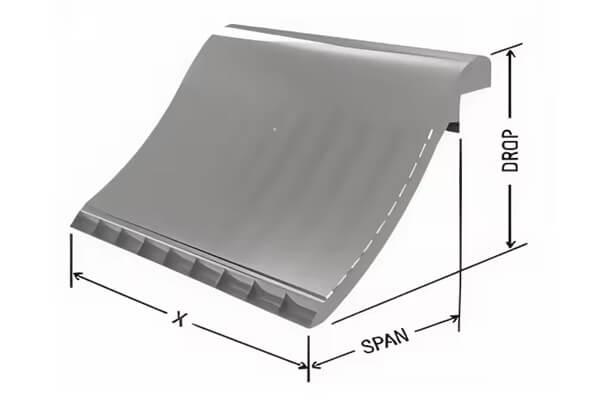

The standard Coanda Intake Screen consists of inclined or curved wedge wire panels installed at the intake entrance.

Key features:

- Curved or sloped wedge wire surface

- V-shaped (triangular) wire profile

- High open area for low head loss

- Fully welded stainless steel construction

- Modular design for easy installation

This type is commonly used in river intakes, canals, reservoirs, and gravity-fed water intake systems.

Coanda Intake Screens

A Coanda Intake Box is a fully integrated intake structure incorporating multiple Coanda wedge wire panels within a box-shaped or chamber-type housing.

Key features:

- Multiple screening surfaces for higher flow capacity

- Compact footprint for space-restricted sites

- Enhanced debris deflection and sediment control

- Direct connection to pipelines or pump stations

Coanda Intake Boxes are ideal for municipal intakes, industrial water supply projects, cooling water systems, and retrofit applications requiring a complete turnkey intake solution.

Working Principle

Coanda Intake Screens

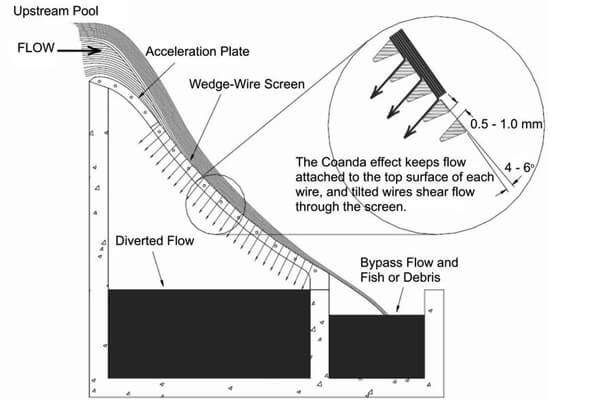

The Coanda Intake Screen operates based on the Coanda Effect, a fluid dynamic phenomenon where water naturally follows a curved surface.

Technical operation process:

- Approach Flow Control

Water approaches the intake screen at a controlled velocity optimized to protect aquatic life. - Coanda Effect Adhesion

When water contacts the curved wedge wire surface, it adheres to the screen and flows along it rather than flowing directly inward. - Selective Filtration Through Slots

Clean water passes through the precision wedge wire slots, while debris, sediment, leaves, algae, and fish are rejected and carried away by the main flow. - Continuous Self-Cleaning

The flow direction and smooth wedge wire profile prevent clogging, eliminating the need for mechanical cleaning or backwashing.

This process ensures stable intake flow, low pressure loss, and uninterrupted operation.

Site Layout

Coanda Intake Screens can be engineered to suit a wide range of site conditions:

- River or Stream Intakes – Installed along riverbanks with screens aligned parallel to flow direction

- Canal Intakes – Mounted on canal walls or beds with inclined orientation

- Lake and Reservoir Intakes – Submerged or semi-submerged configurations

- Pump Station Intakes – Installed upstream of suction pipes

- Gravity-Fed Intake Systems – Positioned before pipelines or treatment facilities

Key site layout considerations include:

- Approach velocity control

- Uniform flow distribution

- Sediment management

- Seasonal water level variation

Advantages

- Self-Cleaning Operation – No moving parts, no backwash, no power consumption

- Non-Clogging Design – Continuous debris rejection using the Coanda Effect

- Low Head Loss – High open area wedge wire construction

- Fish-Friendly Intake – Low approach velocity and precise slot openings

- Corrosion Resistance – High-grade stainless steel materials

- Long Service Life – Robust welded structure for harsh environments

- Low Maintenance Cost – Minimal inspection and operational downtime

- Custom Engineering – Slot size, curvature, and capacity tailored to project requirements

Specification

Typical technical specifications for Coanda Intake Screens and Coanda Intake Boxes (custom designs available):

| Parameter | Specification |

| Product Type | Coanda Intake Screen / Coanda Intake Box |

| Screen Material | Stainless Steel 304 / 316 / 316L (Duplex optional) |

| Wire Profile | V-shaped Wedge Wire |

| Slot Opening | 0.25 mm – 3.0 mm |

| Panel Width | Up to 2000 mm |

| Panel Length | Up to 3000 mm |

| Screen Curvature | Custom hydraulic design |

| Open Area | Up to 60% |

| Flow Capacity | Project-specific |

| Installation Method | Submerged or partially submerged |

Applications

Coanda Intake Screens and Coanda Intake Boxes are widely used in:

- Municipal Drinking Water Intakes

- Irrigation and Agricultural Water Supply

- Hydropower Plant Intakes

- Industrial Process Water Systems

- Cooling Water Intakes

- Desalination Pretreatment Systems

- River, Canal, Lake, and Reservoir Abstraction

- Environmentally Sensitive and Fish-Protection Projects

Request A Quote

* indicates required fields