Pressure Leaf Disc Filters

HOME / MESH FILTER ELEMENTS / Filter Discs / Pressure Leaf Disc Filter

High-Performance Pressure Leaf Filter Elements | Stainless Steel Filter Leaves

Pressure Leaf Filter Elements are the core filtration components for vertical and horizontal pressure leaf systems (VPLF & HPLF). These high-capacity, reusable filter leaves are engineered for efficient solid-liquid separation in demanding industrial environments where high flow rates and reliable filter cake discharge are critical.

Commonly used in the edible oil, chemical, and petrochemical industries, our filter leaves are designed to replace or upgrade existing Niagara-style filter systems. They provide a robust, sustainable alternative to disposable filter media, offering a larger effective filtration area in a compact vessel footprint.

Structure & Design Features of Pressure Leaf Disc Filter

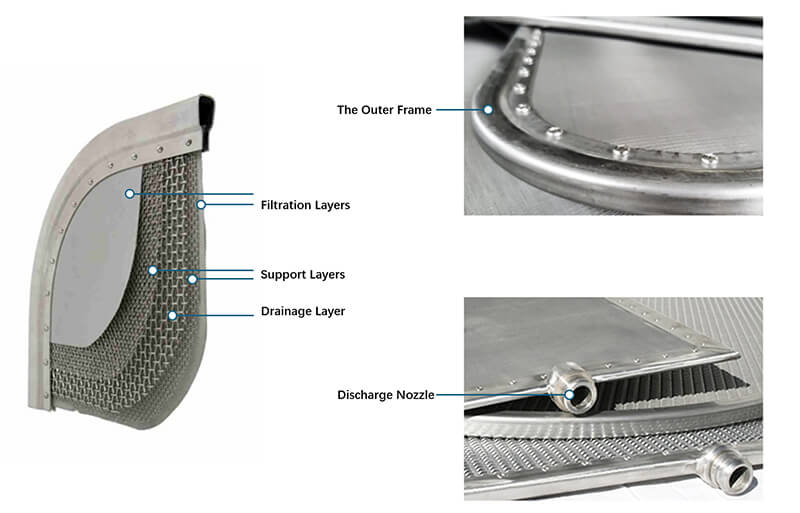

Our Pressure Leaf elements are built for durability and precision. A standard high-performance leaf consists of:

- The 5-Layer Mesh Pack:

- Filtration Layers (2 Outer): Specialized Dutch Weave mesh (typically 24×110 or 60×60) designed to support the filter cake while allowing maximum liquid permeability.

- Support Layers (2 Middle): Coarse mesh that prevents the fine filtration layers from deforming into the drainage chamber.

- Drainage Layer (1 Center): A heavy-duty, oversized internal mesh (e.g., 4×4 mesh) that provides a wide channel for the filtered liquid to travel to the discharge nozzle.

- The Outer Frame: A rigid C-channel profile (Stainless Steel 304/316) that encapsulates the mesh layers. Frames are secured by heavy-duty riveting or continuous TIG welding to prevent edge bypass and ensure the leaf remains perfectly flat.

- Discharge Nozzle: Precision-machined outlet necks with dual O-ring grooves (Viton/EPDM) ensure a 100% leak-proof connection to the central manifold.

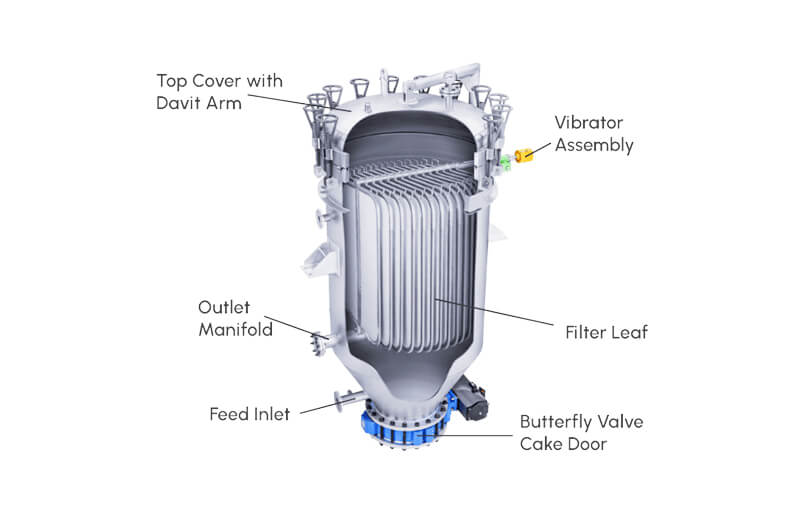

Working Principle of Pressure Leaf Disc Filter

The operation of a Pressure Leaf Filter follows a high-efficiency cyclic process:

- Pre-coating: A mixture of process liquid and filter aid (Diatomaceous Earth or Perlite) is circulated through the leaves. This forms a “pre-coat” layer on the mesh, which acts as the primary filtration barrier.

- Filtration Phase: The slurry is pumped into the vessel. Under pressure (up to 0.6 MPa), the liquid is forced through the cake and mesh layers, into the internal drainage chamber, and out through the manifold. Solids are trapped on the leaf surface, gradually building a uniform filter cake.

- Cake Drying: Once the filtration cycle ends, compressed air or steam is used to blow the remaining liquid out of the cake, reducing product loss and preparing the cake for discharge.

- Cake Discharge: For dry discharge, a pneumatic vibrator on the manifold is activated, shaking the leaves and causing the cake to detach and fall into the hopper. For wet discharge, internal sluicing nozzles wash the cake off the leaves.

Advantages of Pressure Leaf Disc Filter

- Large Filtration Surface: Multi-disc/leaf configurations offer significantly more surface area than standard bags or cartridges.

- Reusability & Sustainability: Built from 100% stainless steel, these leaves are washable and reusable for years, eliminating the cost and waste of disposable filters.

- Superior Mechanical Strength: Engineered to withstand the repetitive stress of vibration-assisted cake discharge without mesh tearing.

- Consistent Filtrate Quality: The rigid internal structure ensures a uniform pre-coat, resulting in crystal-clear filtrate with no bypass.

- Corrosion & Heat Resistance: Available in 304L, 316L, and specialized alloys for acidic or high-temperature processing.

Specification of Pressure Leaf Disc Filter

| Parameter | Technical Data |

| Material of Construction | SS304, SS316, SS316L, 904L, Duplex 2205 |

| Filtration Rating | 20 µm to 200 µm (Standard 5-layer 24×110 mesh) |

| Max Operating Pressure | 0.6 MPa (6 Bar / 87 PSI) |

| Operating Temp. | Up to 250°C (depending on seal material) |

| Shape Options | Rectangular (Horizontal), Circular/Leaf (Vertical) |

| Standard Sizes | 30″, 36″, 48″, 60″ or Custom Dimensions |

| Mesh Design | 3-layer, 5-layer, or 7-layer configurations |

| Specification of Standard Rectangular Leaf Disc Filter Element | |||

Model | Height (mm) | Width (mm) | Filter Area (m2) |

| PFM-RLF-92-54 | 920 | 540 | 1 |

| PFM-RLF-92-60 | 920 | 600 | 1.1 |

| PFM-RLF-92-61 | 920 | 610 | 1.12 |

| PFM-RLF-92-62 | 920 | 620 | 1.14 |

| PFM-RLF-125-45 | 1250 | 450 | 1.13 |

| PFM-RLF-125-66 | 1250 | 660 | 1.65 |

| PFM-RLF-125-72 | 1250 | 720 | 1.8 |

| PFM-RLF-125-77 | 1250 | 770 | 1.93 |

| PFM-RLF-135-90 | 1350 | 900 | 2.43 |

| PFM-RLF-135-100 | 1350 | 1000 | 2.7 |

| PFM-RLF-150-100 | 1500 | 1000 | 3 |

| PFM-RLF-150-120 | 1500 | 1200 | 3.6 |

| PFM-RLF-165-120 | 1650 | 1200 | 3.96 |

| PFM-RLF-165-140 | 1650 | 1400 | 4.62 |

| Specification of Standard Circular Leaf Disc Filter Element | ||

Model | OD (mm) | Filter area (m2) |

| PFM-CLF-600 | 600 | 0.28 |

| PFM-CLF-800 | 800 | 0.5 |

| PFM-CLF-1000 | 1000 | 0.79 |

| PFM-CLF-1200 | 1200 | 1.13 |

| PFM-CLF-1600 | 1600 | 2.01 |

| PFM-CLF-1800 | 1800 | 2.54 |

| PFM-CLF-2000 | 2000 | 3.14 |

Applications of Pressure Leaf Disc Filter

Pressure Leaf Filters are the industry standard for:

- Edible Oil Industry: Bleaching oil, winterization (dewaxing), deodorization, and crude oil polishing.

- Chemical Industry: Recovery of precious metal catalysts, sulphur filtration, organic salts, and resin filtration.

- Food & Beverage: Sugar syrup (thick juice) clarification, glucose, maltose, and fruit juice polishing.

- Petrochemicals: Lube oil additives, waste oil recycling, and biofuel filtration.

- Wastewater Treatment: Brine filtration and industrial sludge dewatering.

Request A Quote

* indicates required fields