Woven Wire Mesh Filter Disc

HOME / MESH FILTER ELEMENTS / Filter Discs / Wire Mesh Filter Disc

Woven Wire Mesh Filter Disc | Stainless Steel Mesh Filtration Discs Manufacturer

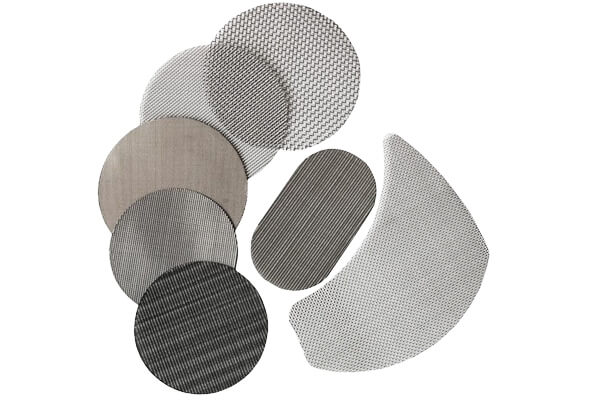

Woven Wire Mesh Filter Discs are precision filtration components manufactured from high-quality woven metal wire mesh and produced through stamping or laser cutting processes. While round filter discs are the most common configuration, woven wire mesh filter elements are not limited to circular shapes and can be custom cut into various geometries according to customer drawings, samples, or specific design requirements.

These filter discs are widely used for solid–liquid separation, gas filtration, particle retention, and flow control in industrial systems. With uniform aperture size, stable woven structure, and excellent mechanical strength, woven wire mesh filter discs deliver reliable and repeatable filtration performance under a wide range of operating pressures and temperatures.

They are commonly installed in filters, strainers, valves, pumps, pipelines, and hydraulic systems, either as single-layer elements or multi-layer assemblies for enhanced filtration efficiency.

Types of Woven Wire Mesh Filter Discs

Woven wire mesh filter discs can be classified according to structure, mesh configuration, and edge treatment:

Single-Layer Woven Mesh Filter Disc

Single-layer woven mesh filter discs are made from a single layer of metal wire mesh, offering a simple yet effective solution for coarse to medium filtration. They are lightweight, cost-effective, and suitable for low-pressure applications where basic particle separation is required.

Sintered Multi-Layer Filter Disc

Sintered multi-layer discs are created by bonding multiple layers of woven mesh through a high-temperature sintering process. This method produces a rigid, durable structure with excellent mechanical strength and high filtration precision, ideal for high-pressure and demanding industrial applications.

Spot-Welded Filter Disc

Spot-welded woven wire mesh discs feature mesh layers welded at specific points to prevent layer displacement during operation. They offer excellent stability under pressure and vibration, making them well-suited for hydraulic, fuel, and oil filtration systems.

Edge-Bound / Framed Filter Disc

Edge-bound or framed discs have their outer edges reinforced with metal strips or rings to prevent fraying and improve sealing performance. This design ensures durability, ease of handling, and suitability for repeated installation or removal in various industrial applications.

Advantages of Woven Wire Mesh Filter Disc

- Precise Filtration Accuracy

Uniform mesh openings ensure consistent particle retention. - High Mechanical Strength

Woven structure provides excellent resistance to pressure and deformation. - Wide Material Availability

Compatible with corrosive, high-temperature, and food-grade environments. - Reusable and Cleanable

Can be cleaned by backflushing, ultrasonic cleaning, or chemical washing. - Customizable Designs

Diameter, mesh count, layers, and edge treatment can be tailored to application requirements. - Long Service Life

Excellent wear resistance and dimensional stability reduce replacement frequency.

Specification of Woven Wire Mesh Filter Disc

| Standard Technical Parameters | |

Parameter | Range / Options |

| Material | Stainless Steel 304, 316, 316L, 310, 321, Copper, Brass, Nickel, Monel, Inconel |

| Wire Diameter | 0.03 – 2.0 mm |

| Mesh Count | 1 – 400 mesh |

| Filtration Rating | 5 μm – 5 mm |

| Disc Diameter | 5 – 500 mm (custom sizes available) |

| Layers | Single layer, double layer, multi-layer |

| Edge Treatment | Raw edge, wrapped edge, welded ring |

| Manufacturing Process | Stamping, laser cutting, spot welding |

| Operating Temperature | Up to 800°C (material dependent) |

Applications of Woven Wire Mesh Filter Disc

Woven wire mesh filter discs are widely used across multiple industries:

- Industrial Filtration

Pipeline strainers

Pump inlet filters

Valve protection filters - Chemical & Petrochemical

Catalyst filtration

Resin and polymer melt filtration

Solvent and chemical fluid purification - Hydraulic & Lubrication Systems

Hydraulic oil filters

Lubricating oil strainers

Fuel filtration components - Food & Beverage

Beverage filtration

Edible oil filtration

Food processing equipment (SS316L recommended) - Pharmaceutical & Laboratory

Fine particle separation

Process media filtration

Equipment protection filters

Request A Quote

* indicates required fields