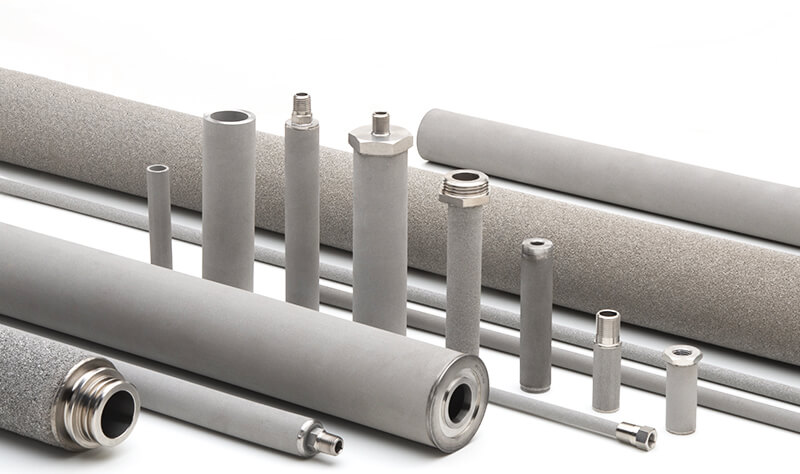

Sintered Porous Candle Filters

HOME / MESH FILTER ELEMENTS / Candle Filters / Sintered Porous Candle Filter

Sintered Porous Candle Filters | Sintered Metal Powder Candle Filters

Sintered porous candle filters—also known as sintered metal powder candle filters—are high-precision filtration elements manufactured by compressing and sintering stainless steel or alloy powders into a rigid, porous structure. The controlled pore size, uniform distribution, and strong mechanical strength make these filters suitable for high-temperature, high-pressure, and corrosive industrial environments.

These candle filters provide absolute or near-absolute filtration efficiency from 0.2 μm to 100 μm, ensuring stable performance in demanding liquid and gas filtration processes. They are widely used across chemical processing, petrochemicals, polymer filtration, pharmaceutical production, food & beverage, and gas purification systems.

Advantages of Sintered Porous Candle Filters

1. Uniform Pore Size & High Filtration Precision

Sintered metal powder forms a stable three-dimensional porous network, ensuring consistent filtration efficiency even under fluctuating pressure conditions.

2. Excellent Mechanical Strength

The rigid metal matrix prevents deformation under high pressure, frequent backwashing, and high-temperature operations.

3. High Temperature & Corrosion Resistance

Applicable in aggressive environments involving acids, alkalis, solvents, and hot gases.

4. Long Service Life & Fully Reusable

Filters can be repeatedly cleaned and regenerated, reducing plant downtime and long-term filtration cost.

5. Stable Flow & Low Pressure Drop

The interconnected pore channels deliver smooth fluid passage and improved process efficiency.

6. Customizable Shapes & Connections

Length, thickness, end-cap design, pore size, and material can be fully customized according to system requirements.

Manufacturing Method of Sintered Porous Candle Filters

Sintered porous candle filters are produced through a highly controlled metal powder sintering process, which ensures uniform pore size, high mechanical strength, and long-term structural stability. The manufacturing steps involve precise material selection, powder preparation, forming, and high-temperature sintering under a protective atmosphere. Below is a detailed overview of the process:

1. Raw Material Selection & Powder Preparation

High-quality metal or alloy powders (such as stainless steel 316L, Inconel, or Hastelloy) are selected based on the required filtration accuracy, chemical resistance, and operating temperature.

- Powders are screened to obtain specific particle size distributions.

- Particle shape, purity, and flowability are carefully controlled to ensure consistent porosity.

2. Powder Mixing & Blending

Metal powders may be mixed with multiple particle size grades to achieve the target pore structure and permeability.

- Fine particles improve filtration accuracy.

- Coarse particles increase permeability and mechanical strength.

3. Cold Isostatic Pressing (CIP) or Molding

The prepared powder is filled into a cylindrical mold and compacted using:

- Cold Isostatic Pressing (CIP) for uniform density

- Hydraulic pressing or uniaxial compression depending on design requirements

This step forms a “green body” with initial shape but without structural integrity.

4. High-Temperature Sintering

The compacted body is placed inside a vacuum or inert-gas furnace (argon, hydrogen atmosphere).

- Sintering occurs at temperatures typically between 1100°C and 1350°C, depending on alloy.

- Adjacent metal particles diffuse and bond at atomic contact points.

- A rigid, porous, and homogeneous structure is formed with permanent metallurgical bonds.

This step determines the final porosity, permeability, and mechanical properties.

5. Machining & Precision Finishing

After sintering, the solid porous candle is machined to final dimensions:

- Turning, milling, grinding

- Surface trimming

- Threading or welding of end caps, flanges, or adapters

The component maintains its porosity during machining due to its high structural strength.

6. Quality Control & Testing

Each candle filter undergoes strict inspection to ensure performance consistency:

- Pore size distribution test (using bubble point or porometry)

- Filtration accuracy testing

- Pressure drop and flow rate measurement

- Mechanical strength and collapse pressure test

- Corrosion and temperature resistance evaluation

7. Assembly & Customization

Depending on the system design, filters can be produced with:

- Threaded ends

- Flanged ends

- Double-open-end designs

- Customized sealing methods (O-ring groove, gasket, metal-to-metal seal)

All customized features are integrated while maintaining the internal porous structure.

Connector Types of Sintered Porous Candle Filters

Sintered porous candle filters can be equipped with various connector types to fit different filtration systems. The most common options include:

1. Threaded Connections

Available in NPT, BSP, metric, or customized threads.

2. Flanged Ends

ANSI, DIN, JIS, and custom flanges available.

3. Double Open End (DOE)

Common types: 222/Flat, 226/Flat, Flat–Flat.

4. Single Open End (SOE)

Includes 222, 226, and bayonet-style ends.

5. Welded End Caps

Stainless steel or alloy end caps welded directly to the filter.

6. Sanitary & Quick-Clamp Fittings

Tri-Clamp and other sanitary connectors.

7. Custom Designs

Customized threads, flanges, or sealing structures available upon request.

Specification of Sintered Porous Candle Filters

| Category | Details |

| Material Options | SS304, SS316L (most common), Inconel 600/625, Hastelloy C22/C276, Monel, Titanium, Nickel |

| Filtration Rating | 0.2–100 μm (customizable) |

| Porosity | 25–45% depending on grade |

| Shape / Structure | Cylindrical candle, hollow core, threaded or flange end, welded bottom cap |

| Dimensions | Diameter: 30–80 mm · Length: 250–1500 mm(customizable) |

| Working Temperature | Up to 600°C for SS316L;higher for special alloys. |

| Working Pressure | Up to 3 Mpa |

| Connection Types | DOE, SOE, 222/226 O-ring, NPT thread, Flange type |

| Manufacturing Method | Metal powder isostatic pressing + high-temperature sintering |

| Cleaning Method | Backwashing, ultrasonic cleaning, chemical cleaning, reverse air pulse |

Applications of Sintered Porous Candle Filters

1. Gas Filtration

Sintered porous candle filters are widely used for hot gas filtration in demanding industrial processes, where operating temperatures frequently exceed 750°C for extended periods. These systems typically feature automatic self-cleaning or pulse-jet regeneration, requiring filter elements with excellent thermal stability, mechanical strength, and complete regenerability.

Sintered powder metal filters meet all these requirements, making them the preferred choice for industries such as chemical processing, metallurgy, thermal energy, and catalyst recovery.

2. Sparging

Many high-pressure systems require porous metal elements to achieve efficient gas–liquid contact, such as in stripping, mixing, aeration, carbonation, and diffusion reactions.

Our sintered metal sparger elements provide:

- Uniform gas distribution

- High mechanical strength

- Corrosion resistance

- Stable and repeatable mass transfer efficiency

We can design custom spargers based on flow rate, pressure, bubble size requirements, and reactor conditions to maximize process performance.

3. Liquid Filtration

We supply precision sintered metal filter elements capable of achieving 0.1 µm filtration efficiency in liquids. These elements can be manufactured with dual-layer or multi-layer powder structures, ensuring:

- Consistent pore size

- Lower pressure drop

- Higher flow capacity

- Excellent backwash and chemical cleaning performance

They are ideal for catalyst filtration, polymer filtration, fine chemical production, and high-purity processing. The solid-state sintered structure (no welding) offers exceptional durability and significantly longer service life than conventional filter designs.

4. Fluidizing

Sintered porous metal components are widely used in fluidizing systems to achieve stable gas distribution for powders, granules, and chemical media.

We manufacture custom designs—including plates, cones, and discs—using materials such as stainless steel, bronze, and polyethylene.

Benefits include:

- Uniform airflow

- Excellent mechanical strength

- Self-supporting structure

- Optional flanges and custom connectors

These solutions are commonly used in drying beds, powder handling, pneumatic conveying, and mixing systems.

Request A Quote

* indicates required fields