Five-Layer Sintered Mesh

HOME / SCREEN MESH MATERIALS / Sintered Mesh / Five-Layer Sintered Mesh

Five-Layer Sintered Mesh | Standard Stainless Steel Sintered Wire Mesh Filter

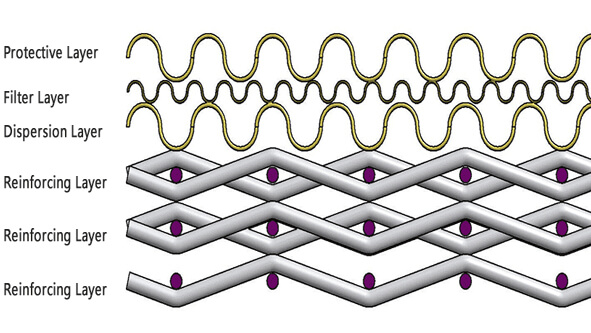

The Five-Layer Sintered Mesh, also known as the Standard Type Sintered Wire Mesh, is the most classic and widely used structure among sintered mesh filter materials. It is composed of five precisely selected layers of stainless steel woven wire mesh that are bonded together through vacuum sintering and diffusion bonding. Each layer serves a specific function, forming a single, strong, and porous metallic laminate with high mechanical strength, uniform pore size, and reliable filtration performance.

This structure combines excellent rigidity with stable permeability and is suitable for a wide range of industrial filtration and separation processes, especially in high-pressure or high-temperature environments.

Standard Five-Layer Structure

The typical configuration includes the following layers:

- Protective Layer – safeguards the filtration layer from direct mechanical damage.

- Dispersion Layer – evenly distributes the flow to optimize filtration efficiency.

- Fine Filtration Layer – provides precise particle retention and filtration accuracy.

- Support Layer – ensures overall mechanical strength and pressure resistance.

- Reinforcing Layer – enhances structural rigidity and durability during operation.

These five layers are diffusion-bonded together to form an integrated porous medium. The result is a filter material that offers high strength, excellent backwash performance, and consistent flow characteristics.

Advantages of Five-Layer Sintered Mesh

- High mechanical strength and structural rigidity – performs under high pressure and stress.

- Consistent filtration accuracy – uniform pore size ensures repeatable results.

- Excellent permeability with low pressure drop – enhances operational efficiency.

- Corrosion and high-temperature resistance – suitable for aggressive chemical environments.

- Easy cleaning and long service life – supports repeated backwashing and reuse.

- Versatile processing capability – can be cut, welded, rolled, or formed into filter elements.

Specification of Five-Layer Sintered Mesh

- Material Options: SS304, SS316L, Duplex Stainless Steel, Inconel, Monel, Hastelloy.

- Layer Structure: 5 layers (Protection + Dispersion + Filtration + Support + Reinforcing).

- Filtration Rating: 1–200 microns (customizable).

- Thickness: 1.0 mm – 2.0 mm.

- Maximum Operating Temperature: up to 600°C.

- Maximum Pressure Resistance: up to 3000 kPa.

- Available Forms: filter discs, cylindrical cartridges, cones, plates, and custom shapes.

| Filtration Performance of Standard 5-Layer Sintered Mesh | |||||||||

| Nominal Filter Rating (μm) | Protection Layer | Filtration Layer | Separation Layer | Reinforcing Layer | Reinforcing Layer | Thickness (mm) | Air Permeability (L/min/cm2) | Bubble Point Pressure (Pa) | Weight (kg/m2) |

| 1 | 100 | 400 × 3000 | 100 | 12 × 64 | 64 × 12 | 1.7 | 1.81 | 360–600 | 8.4 kg/m2 |

| 2 | 100 | 325 × 2300 | 100 | 12 × 64 | 64 × 12 | 1.7 | 2.35 | 300–590 | |

| 5 | 100 | 200 × 1400 | 100 | 12 × 64 | 64 × 12 | 1.7 | 2.42 | 260–550 | |

| 10 | 100 | 165 × 1400 | 100 | 12 × 64 | 64 × 12 | 1.7 | 3 | 220–500 | |

| 15 | 100 | 165 × 1200 | 100 | 12 × 64 | 64 × 12 | 1.7 | 3.41 | 200–480 | |

| 20 | 100 | 165 × 800 | 100 | 12 × 64 | 64 × 12 | 1.7 | 4.5 | 170–450 | |

| 25 | 100 | 165 × 600 | 100 | 12 × 64 | 64 × 12 | 1.7 | 6.12 | 150–410 | |

| 30 | 100 | 400 | 100 | 12 × 64 | 64 × 12 | 1.7 | 6.86 | 120–390 | |

| 40 | 100 | 325 | 100 | 12 × 64 | 64 × 12 | 1.7 | 7.1 | 100–350 | |

| 50 | 100 | 250 | 100 | 12 × 64 | 64× 12 | 1.7 | 8.41 | 90–300 | |

| 75 | 100 | 200 | 100 | 12 × 64 | 64 × 12 | 1.7 | 8.7 | 80–250 | |

| 100 | 100 | 150 | 100 | 12 × 64 | 64 × 12 | 1.7 | 9.1 | 70–190 | |

| 150 | 50 | 100 | 50 | 30×30 | 100 × 50 | 2.0 | 25 | 50-150 | |

| 200 | 40 | 80 | 40 | 20×40 | 80 × 40 | 2.0 | 26 | 50-150 | |

Applications of Five-Layer Sintered Mesh

The Five-Layer Sintered Mesh is ideal for filtration and flow control in demanding industries:

- Chemical and Petrochemical Filtration – catalyst recovery, polymer filtration, and process gas filtration.

- Polymer and Plastic Processing – melt filtration, extrusion, and fiber spinning.

- Oil and Gas Filtration – used in coalescing, gas-liquid separation, and sand control systems.

- Water Treatment and Wastewater Filtration – reliable fine and coarse filtration media.

- Pharmaceutical and Food Processing – ensures clean, hygienic, and stable filtration.

- Hydraulic and Pneumatic Systems – high-pressure filters and protective screens.

Request A Quote

* indicates required fields