Multi-Layer Sintered Mesh

HOME / SCREEN MESH MATERIALS / Sintered Mesh / Multiple Layer Sintered Mesh

Multi-Layer Sintered Mesh | Stainless Steel Diffusion-Bonded Filter Media

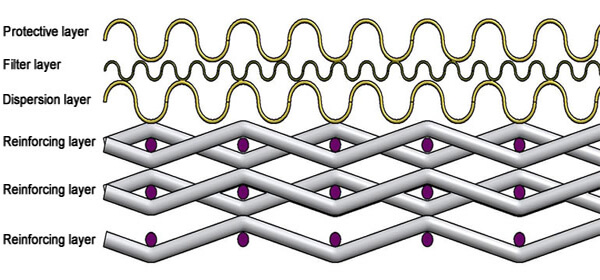

Multi-Layer Sintered Mesh is a high-strength and precision-engineered metal filter medium made by laminating multiple layers of woven wire mesh through a controlled sintering process. During production, several layers of stainless steel wire mesh—each with a specific mesh count and function—are stacked and bonded together in a high-temperature furnace under mechanical pressure. The diffusion-bonding process permanently joins the wires at their contact points, creating a rigid, porous structure with uniform filtration performance and excellent mechanical integrity.

This composite mesh structure is stronger, more stable, and more reliable than traditional woven mesh. It maintains consistent pore geometry, even under high pressure or temperature, making it ideal for demanding filtration and separation applications.

Layer Structure & Composition

The most common configuration is the five-layer sintered mesh, which includes:

- Protective Layer – protects the filtration layer from mechanical damage.

- Dispersion Layer – distributes the flow evenly to prevent localized clogging.

- Fine Filtration Layer – provides accurate filtration of solid particles.

- Support Layer – enhances the mechanical strength of the filtration layer.

- Reinforcing Layer – provides structural stability and load-bearing capacity.

Other multi-layer combinations (three, four, six, or more layers) can be customized according to specific filtration requirements, flow rates, and working conditions.

Advantages of Multi-Layer Sintered Mesh

- High mechanical strength and rigidity – withstands high differential pressure and stress.

- Precise and stable filtration accuracy – uniform pore size distribution ensures reliable results.

- Excellent permeability and low pressure drop – supports efficient flow rates.

- Corrosion, heat, and pressure resistant – suitable for harsh working environments.

- Easy cleaning and backwashable – reusable, reducing operational costs.

- Customizable multi-layer structure – allows tailored performance for various processes.

Specification of Multi-Layer Sintered Mesh

- Material Options: SS304, SS316L, Duplex Stainless Steel, Inconel, Monel, Hastelloy, Titanium.

- Typical Layer Structure: 3–7 layers (5-layer standard).

- Filtration Rating: 1–200 microns (customizable).

- Thickness: 0.5 mm – 3.5 mm.

- Maximum Operating Temperature: up to 600°C (depending on material).

- Maximum Pressure Difference: up to 3000 kPa.

- Available Forms: discs, cylinders, cones, panels, and filter elements.

| Two and Three Layers Sintered Mesh Laminate | |||||

| Product code | Layer number | Structure | Filter rating (µm) | Overall thickness (mm) | Weight / sq.ft (kg) |

| PFM-MLSM-201 | 2 | 100 × 0.0045″ / 200 × 1400 | 5 | 0.2286 | 0.1135 |

| PFM-MLSM-202 | 2 | 10 × 0.025″ / 325 × 0.0014″ | 44 | 0.9144 | 0.2088 |

| PFM-MLSM-203 | 2 | 60 × 0.0075″ / 325 × 0.0014″ | 44 | 0.36576 | 0.1271 |

| PFM-MLSM-204 | 2 | 10 × 0.025″ / 250 × 0.0016″ | 55 | 0.9398 | 0.2088 |

| PFM-MLSM-205 | 2 | 10 × 0.025″ / 200 × 0.0021″ | 74 | 0.9525 | 0.2179 |

| PFM-MLSM-206 | 2 | 30 × 0.012″ / 150 × 0.0026″ | 105 | 0.4953 | 0.168 |

| PFM-MLSM-207 | 2 | 10 × 0.025″ / 150 × 0.0026″ | 105 | 0.4953 | 0.2177 |

| PFM-MLSM-208 | 2 | 60 × 0.0075″ / 100 × 0.0045″ | 140 | 0.51308 | 0.1725 |

| PFM-MLSM-209 | 2 | 10 × 0.025″ / 100 × 0.0045″ | 140 | 0.96266 | 0.2542 |

| PFM-MLSM-210 | 2 | 20 × 0.016″ / 20 × 0.016″ | 864 | 0.8128 | 0.3178 |

| PFM-MLSM-301 | 3 | 60 × 0.0075″ / 325 × 2300 / 60 × 0.0075″ | 2 | 0.56642 | 0.2633 |

| PFM-MLSM-302 | 3 | 60 × 0.0075″ / 200 × 1400 / 60 × 0.0075″ | 5 | 0.62738 | 0.2906 |

| PFM-MLSM-303 | 3 | 60 × 0.0075″ / 165 × 1400 / 60 × 0.0075″ | 10 | 0.72136 | 0.2906 |

| PFM-MLSM-304 | 3 | 60 × 0.0075″ / 165 × 800 / 60 × 0.0075″ | 15 | 0.62738 | 0.2679 |

| PFM-MLSM-305 | 3 | 60 × 0.0075″ / 80 × 700 / 60 × 0.0075″ | 25 | 0.86106 | 0.2838 |

| PFM-MLSM-306 | 3 | 60 × 0.0075″ / 325 × 0.0014″ / 60 × 0.0075″ | 44 | 0.62484 | 0.2361 |

| PFM-MLSM-307 | 3 | 60 × 0.0075″ / 250 × 0.0016″ / 60 × 0.0075″ | 55 | 0.6223 | 0.2361 |

| PFM-MLSM-308 | 3 | 60 × 0.0075″ / 200 × 0.0021″ / 60 × 0.0075″ | 74 | 0.64262 | 0.2452 |

| PFM-MLSM-309 | 3 | 60 × 0.011″ / 100 × 0.0045″ / 200 × 0.0021″ | 74 | 0.72898 | 0.1998 |

| PFM-MLSM-310 | 3 | 60 × 0.0075″ / 150 × 0.0026″ / 60 × 0.0075″ | 105 | 0.65786 | 0.2497 |

| PFM-MLSM-311 | 3 | 60 × 0.0075″ / 100 × 0.0045″ / 60 × 0.0075″ | 140 | 0.76708 | 0.2815 |

| Four-layer Sintered Mesh Laminate | |||||

| Product code | Layer number | Structure | Filter rating (µm) | Overall thickness (mm) | Weight / sq.ft (kg) |

| PFM-FLSM-401 | 4 | 60 / filter layer / 40 / 20 | 2 – 200 | 1 | 0.4088 |

| PFM-FLSM-402 | 4 | 40 / filter layer / 20 / 16 | 2 – 200 | 1.7 | 0.576 |

Six-layer sintered mesh laminate

- Filter rating: 1 µm to 100 µm.

- Overall thickness: 3.5 mm.

- Standard size: 1000 mm × 1200 mm.

Seven-layer sintered mesh laminate

- Structure: 50 / filter layer / 40 / 20 / 40 / filter layer / 50.

- Thickness: 2 mm.

- Filter rating: 2 µm – 150 µm.

- Weight: 7.4 kg/m2.

- Porosity: 58%.

Applications of Multi-Layer Sintered Mesh

Multi-Layer Sintered Mesh is widely used in industries that demand precise, durable, and cleanable filtration media:

- Chemical and Petrochemical Filtration – filtration of catalysts, resins, and polymers.

- Polymer and Plastic Processing – used in extrusion and spinning filters.

- Oil and Gas Systems – for solid-liquid and gas-solid separation under pressure.

- Water Treatment and Filtration Units – reliable for fine and coarse filtration.

- Hydraulic and Pneumatic Systems – ensures protection of sensitive components.

- Food and Pharmaceutical Industries – suitable for hygienic and high-temperature filtration processes.

Request A Quote

* indicates required fields